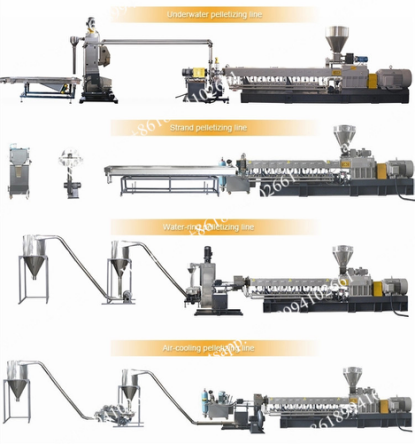

Application for water-cooling strand

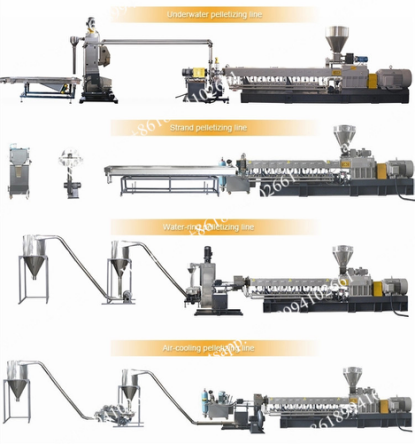

1. Fiber reinforcement and modification: filling glass fiber or carbon fiber for: PP, PA, PBT, ABS, AS, POM, PPS, PET, etc

2. Ploymer compounding: PC+ABS, PA+ABS,CPE+ABS,PP+EPDM,PA+EPDM,

PA+SBS, etc.

3. Filling modified: Filling CaCO3,Talc,Titanium, carbon black for PVC PE,PP, EVA etc.

4. Cable material: cable sheath, cable insulation compounds,crosslinking compounds, optical fiber protection compounds, cable coating material, thermal contraction material,etc.

5. Dedicated material: PPR pipe compounds, PE crosslinking tube material, cigarettes filter tip material, acetate fiber material, etc.

6. High Concentration Color Masterbatch: PE,ABS,PS,EVA,PET,PP + color +

additives, etc.

7. Flaming Retardants: PVC, PP, PA, ABS, EVA, PBT + flame retardants, etc.

8. Special Functional Masterbatch: double protection masterbatch, antistatic masterbatch, anti-bacteria masterbatch, thermal insulation masterbatch, hypothermia material, etc.

9. The degradable masterbatch: PP, PE, PS + starch+ additives, etc.

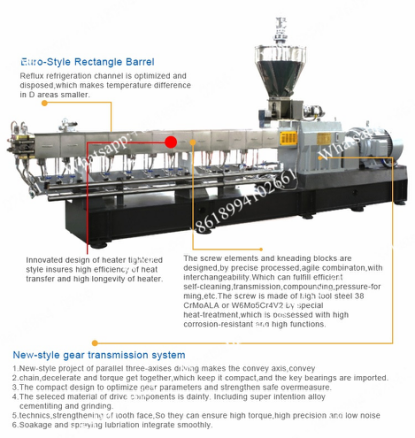

Features:

Barrel and screw clear easily

Materials changing in each section of barrel can be observed

Plasticizing performance is good, and extrusion pressure is big, so that color masterbatch material can be mixed uniformly and pigment ratio is high.

.png) Contact Now

Contact Now