|

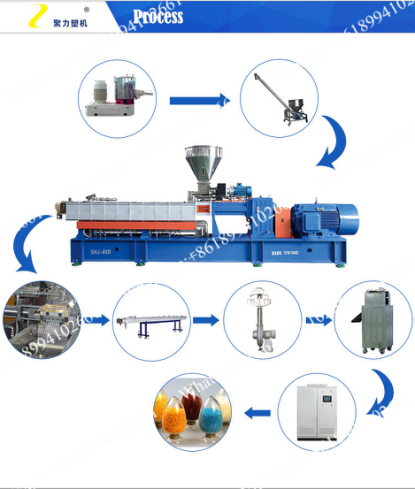

Process

|

Representative materials

|

|

Mixing nature-changing

|

PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA +Silicon rubber, etc.

|

|

PE,PA,PC,CPE+ABS(alloy),PBT+PET,PP+ PE etc.

|

|

Filling nature-changing

|

PE,PP,EVA, etc.+ Calcium carbonate, talcum powder, titanic powder

ABS,PC,PS, etc.+ aluminum hydroxide, magnesium hydroxide, antimony oxide.

|

|

PP,PA,ABS +ferrous powder, sulphuric powder ceramic powder

|

|

Functional machine pellets

|

PP,PA,ABS,PBT, etc+ anti-burning agent and other auxiliary agents: combustion-supporting machine pellets

|

|

PE,PP,PS, etc+ starch: de-composing machine pellets

|

|

PE+ fog-preventing dipper, stabilizer: dual-prevention machine pellets

|

|

PE,EVA=ABS etc+ carbon black: black machine pellets

|

|

Colored machine pellets

|

PE,PP,ABS,AS,PA,EVA,PET +pigment and auxiliary

|

|

Intensified glass fibers and carbon fibers

|

PP,PBT,ABS,AS,PA,PC,POM,PPS,PET etc.+ long fibers, small fibers, carbon fibers, crystals and so on, etc.

|

|

Various cables

|

HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP, etc. insulating cables,coatings,

PE peroxide silicon alkyl crossing cables: radialization crossing cables

|

|

Special materials

|

EVA heat-melting glue, polyurethane, fluorine rubber, fluorine plastics, PP cigarette filtering material and TPR sole material

|

|

Reaction extruding

|

Poly-amide condensate, poly-amide melting polymerization, poly-amide polythene-adding, poly-carbonate condensate, etc.

|

|

Exhausting and volatilization

|

Polystyrene oxide, high-absorbing resin, chlorine sulphur polyethylene

|

|

Powder paint

|

Polyester, ring oxide, lactide, polyurethane, acrylate

|

.png) Contact Now

Contact Now