Product Description

Polyethylene Twin Screw Extruder Features:

1.Even plastication and agglomeration,

2.Reliable quality,

3.Long servicing life and direct conversion of powder into plastic products.

4.Equipped with our company's different mould tools down stream equipment, they can directly produce plastic products like pipes,rods, plates and profiles.

Polyethylene Twin Screw Extruder Application:

Advertisement: such as screen printing, computer lettering, ad board.

Architeture: such as buliding wall board, decoration board, housing, office, public buliding interlayer, commercial decoration shelf, non-dust room board, ceiling plate.

Transportation: such as steamship, aeroplane, carriage, traine compartment, roof shed, case core layer, inner upholster.

Industry: such as chemical industry antisepticizing project, thermoforming , for refrigeratory, for temperature keeping, for environment protection

|

Underwater

pelletizing system

|

Pelletizer for the production of almost all thermoplastics, hot melt adhesives,

especially for some low hardness and high viscosity materials

|

|

Strand

pelletizing system

|

Pelletizer for the processing of the melted polymer to cylindrical,

dry and easy to handle plastics pellets

|

|

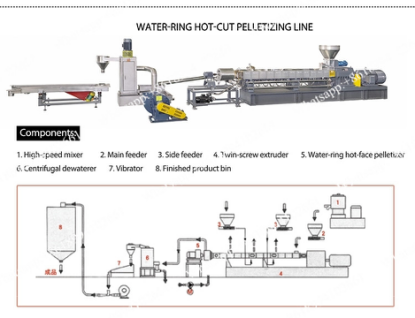

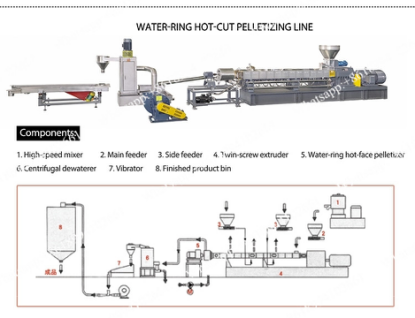

Water ring

pelletizing system

|

Pelletizer for the production of various masterbatch,

filled and reinforced products etc.

|

|

Air cooling

pelletizing system

|

Pelletizer for the production of temperature and shear-sensitive plastics

|

Why choose us

1. Energy-saving:

All main motors of machine use Variable Frequency Motor(AC), eliminating three-phase asynchronous motors;

Variable Frequency Motor:

(1) Speed regulation is easy and energy saving.

(2) AC motor has simple structure, small volume, small inertia, low cost, easy maintenance and durability.

(3) It can expand output and achieve high speed and high voltage operation.

(4) Soft start and fast brake can be achieved.

(5) No spark, explosion-proof, and strong environmental adaptability.

2.High output:

Take "PP" material as an example, the PP material is tested on the customer's site, our machines' actual production output is 10%-20% higher than the same model in the market;

3.Simple installation:

The equipment is easy to install, only need to be connected to the inlet and outlet water, which can save 2 days of installation time;

4.Advanced design:

(1)All electrical components are imported famous brands, like German "SIEMENS", France "SCHNEIDER", United States "CEME", Japan "ORMON" "TOSHIBA" "FUJI" etc.;

(2)The industry's first advanced dust cover design, beautiful appearance and simple maintenance;

(3)Use a thicker and more heat-resistant heater to ensure the heating effect of the barrel and the service life of the heater;

5.Others:

(1)Available production video reference;

(2)At the discretion, lead customers to visit the customer site;

6.Good after-sales service:

(1)Modernized CNC processing equipment to fundamentally guarantee the supply of quantity and quality of equipment spare parts;

(2)We provide engineers overseas installation service.

.png) Contact Now

Contact Now