Product Description

pp color masterbatch production line/sulfur masterbatch/filler masterbatch pelletizing line

· Tailored structure,stable performance, easy to operate.

· There are varied speeds and fraction ratios available, which can satisfy most customers’ formula and processing requirements.

· Frame, frame cap and base, looking very nice, are welded and treated by annealing for stress relieving.

· Chilled alloy cast iron roll is abrasion resistant with long service life.

· The speed reducer is the hard-tooth surface gear reducer of Class 6 precision, which has long service life and low noise.

· Perfect emergency stop device can ensure the safety of personnel and equipment.

· The seal structure with special design can eliminate the leaking phenomenon of lubricating oil.

· Stock pan is easy to clean up with dislodging device.

· Human nature designed operating system reduces labor intensity.

· Modular structure offers various structures for customers’ option.

· The flexible design system can satisfy customers’ special design requirements within the shortest time.

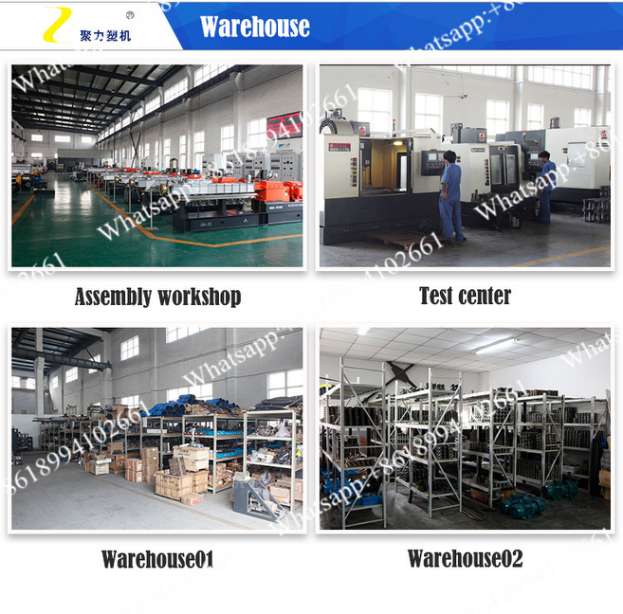

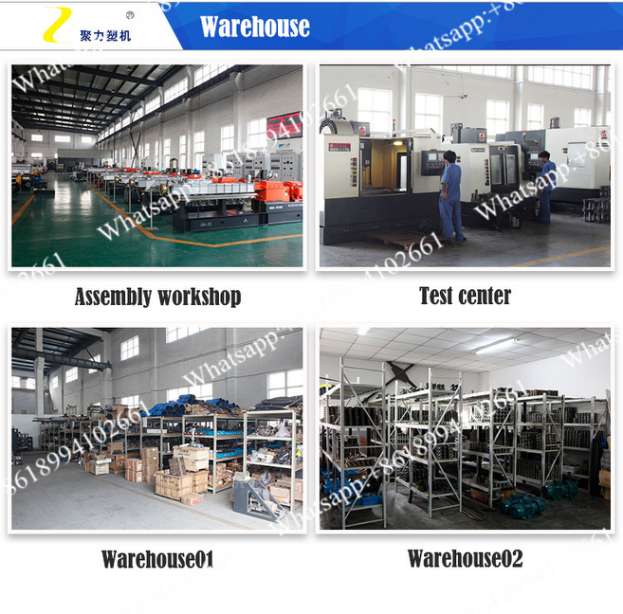

· A load test running will be made to the assembled equipment in our company to save debugging time for customers.

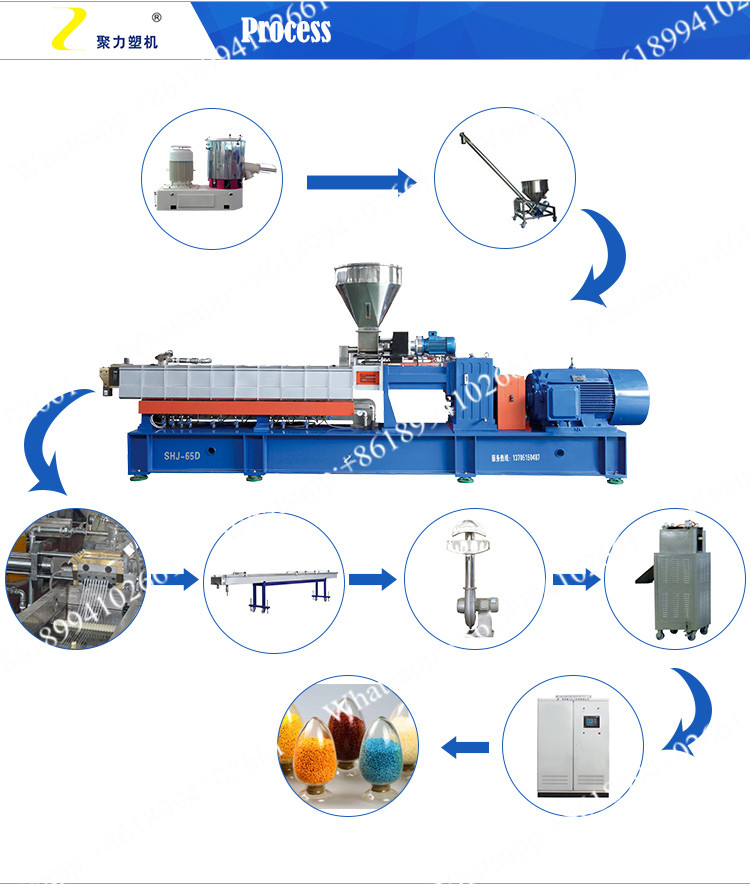

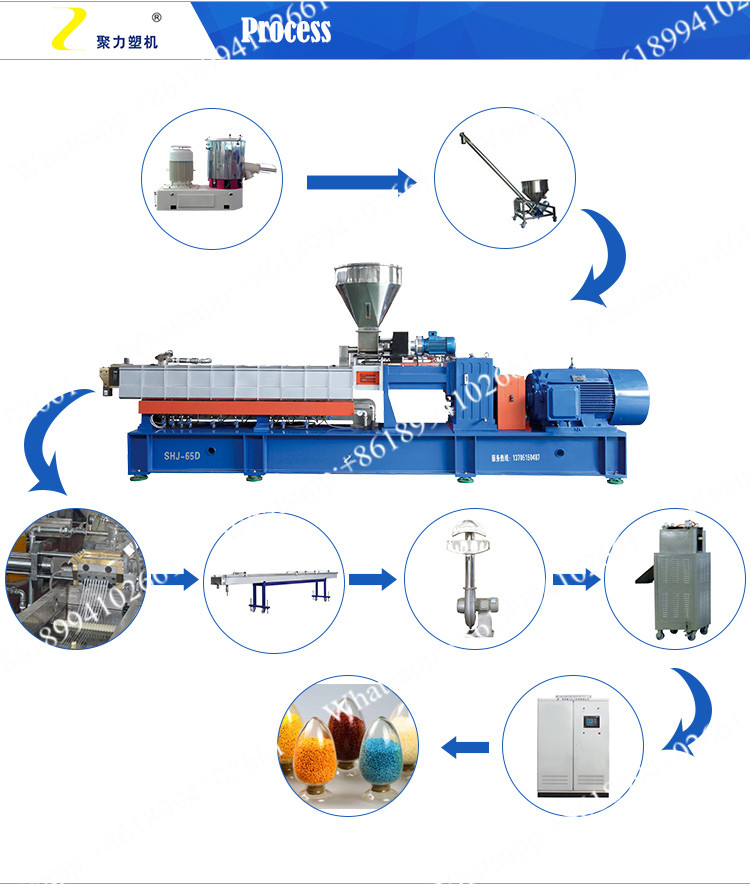

Co-rotating Parallel Twin

Screw Extruder Features

1. Screw components designed by computer aids is

kneading type, has excellent self-cleaning function, the new kneading

block design effectively avoid the problems of overheating and energy

consumption.

2. According to process system and formula requirements, the

unit can optimize its L/D ratio, barrel structure, screw array, venting

number and location, feeding method, electrical control methods etc. for

rational allocation.

3. Granulation system: water-cooling strand pelletizing,

air-cooling die face hot cutting, water ring die face hot cutting, Eccentric

water mist hot cutting, water and underwater die face hot cutting and so on.

4. Application: Filling Modification, glass fiber (carbon

fiber) enhance various kinds of master batch, rubber and plastics

compounding, plastic alloys, functional master batch, Various kinds

of electric cable material, reactive extrusion. Devolatilization

process, powder coating and so on.

|

Underwater

pelletizing system

|

Pelletizer for the production of almost all thermoplastics, hot

melt adhesives,

especially for some low hardness and high viscosity materials

|

|

Strand

pelletizing system

|

Pelletizer for the processing of the melted polymer to cylindrical,

dry and easy to handle plastics pellets

|

|

Water ring

pelletizing system

|

Pelletizer for the production of various masterbatch,

filled and reinforced products etc.

|

|

Air cooling

pelletizing system

|

Pelletizer for the production of temperature and shear-sensitive plastics

|

Pre-sales service:

• Introducing in detail features and application of the

products to customer

• Selecting rconomical and practical machine&equipment

for customer

• Providing operation data of the related

machine&equipment

• Providing means of trial performance for customer

Sales service:

• Recommending engineering conditions required for

installation of the machine&equipment

• Communication in time the manufacturing progress of the

machine with user

• Providing assistance in technical conditions,screw

combination and barrel disposition needed for product

After-sales service:

• Providing on-the-spot technical assistance in

installation,commissioning and training

• Filling in detail customer's information

• Providing long-term maintenance service and spare parts

• Giving technical support to customer for developing new

product

• Providing free maintenance for a year

.png) Contact Now

Contact Now