Basic Info

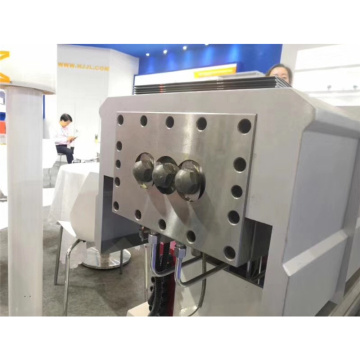

Model No.: SHJ 65

Raw Material: PP

Screw: Multi-Screw

Inverter: Inverter, Switzerland "ABB", Japan"TOSHIBA""FUJI" ETC.

Electromagnetic Heater: Electromagnetic Heater

Automation: Automatic

Computerized: Computerized

Customized: Customized

Certification: CE, ISO9001:2008, SGS

Condition: New

Name: PP Face Mask Non-woven Melt Blown Granules Extruder

Type: Co-rotating Twin Screw Extruder

Plastic Processed: Melt Blown And Non-woven Fabric

Application: Granules, Pelletizing, Melt Blown Non-woven Fabric Granules Making Machine

Voltage: 380V/50HZ(Or Customized)

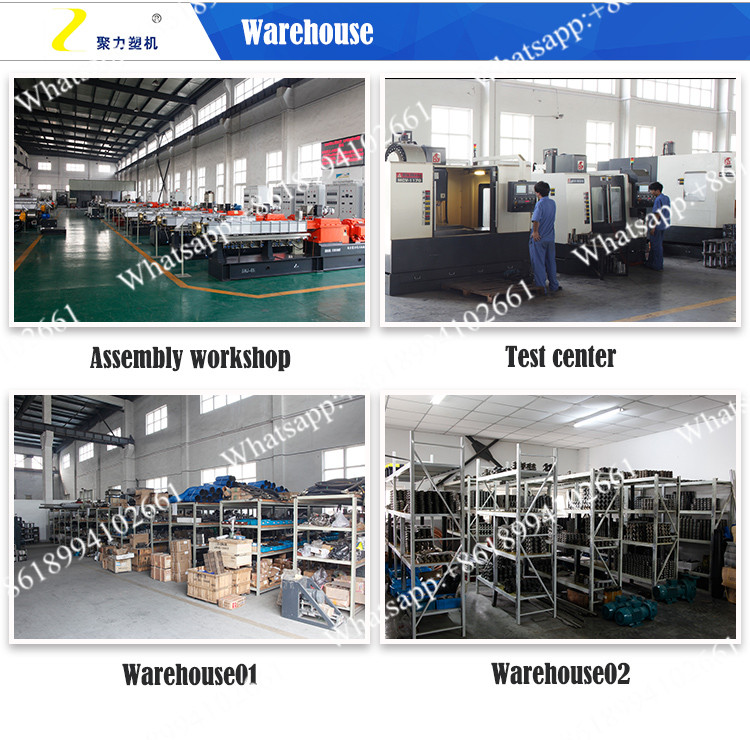

Applicable Industries: Manufacturing Plant, Machinery Repair Shops, Printing Shops

Key Selling Points: Melt Blown Non-woven Fabric Granules Making Machine

Brand Of Switches And Instruments: France "Schneider","OMRON"

Motor Brand: Germany "SIEMENS" Variable Frequency Motor

.png) Contact Now

Contact Now