Product Description

Application scope: This series can be used in universitys' experiments

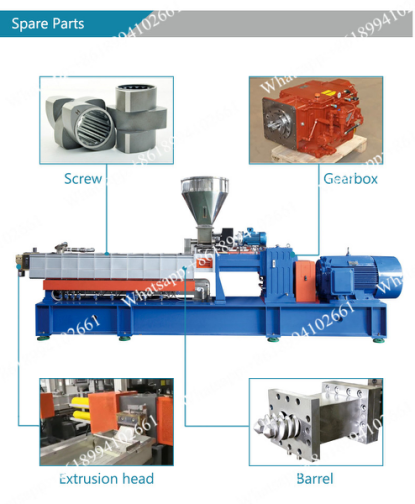

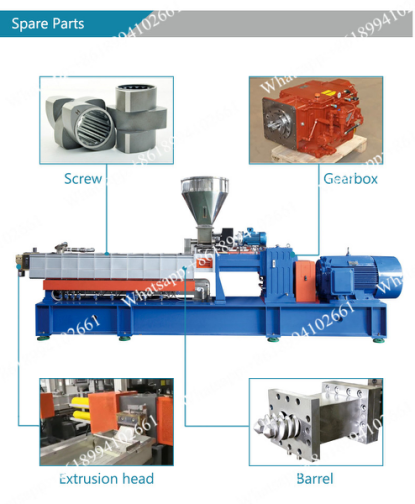

The machine screw be designed by using toy bricks principle, which optimize and enables the machine to achieve perfect state on the basis of different material element; craft request; style of screw element; barrel; slender ratio; feeding apparatus; screen changer; cutting system; electric control module. The machine will realize multifunction, meanwhile can also satisfy multipurpose of give attention to two or more things and special-purpose. Our machinery has the characteristic of high production, low energy consumption.

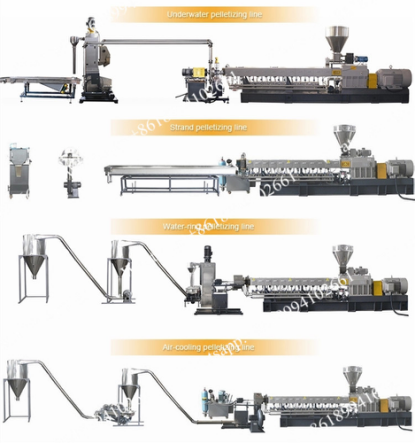

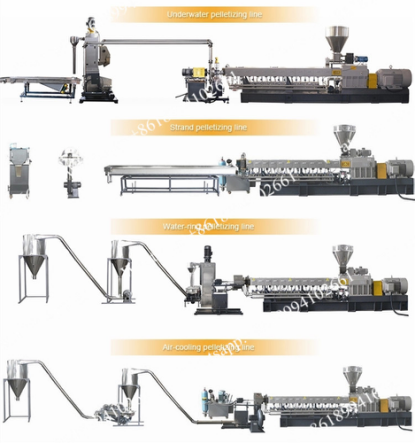

Parallel co-rotating twin screw extruders have excellent mixing performance, good selfcleaning performance and flexible modular configuration characteristics which make them suitable for processing different types of material systems, and are extensilverly used in fields of polymer processing, foodstuff processing and chemical products, especially for various high molecular materials.

1.Technical Data:

|

Type

|

Series

|

D(mm)

|

L/D

|

n(r/min)

|

P(kw)

|

T(N.m)

|

T/A³

|

Q(kg/h)

|

|

SHJ-20

|

A

|

21.7

|

32-60

|

400

|

3

|

30

|

4.8

|

2~10

|

|

B

|

600

|

4

|

30

|

4.8

|

5~15

|

|

SHJ-35

|

A

|

35.6

|

32-60

|

400

|

11

|

125

|

4.6

|

10~40

|

|

B

|

600

|

15

|

115

|

4.2

|

15~55

|

|

C

|

600

|

22

|

165

|

6.1

|

40~95

|

|

D

|

600

|

30

|

225

|

8.3

|

70~120

|

|

SHJ-50

|

A

|

50.5

|

32-60

|

500

|

45

|

405

|

5.1

|

120~200

|

|

B

|

600

|

55

|

415

|

5.2

|

155~255

|

|

C

|

600

|

75

|

565

|

7.1

|

200~355

|

|

D

|

600

|

90

|

680

|

8.5

|

255~400

|

|

SHJ-65

|

A

|

62.4

|

32-60

|

500

|

75

|

680

|

4.8

|

200~355

|

|

B

|

600

|

90

|

680

|

4.8

|

255~400

|

|

C

|

600

|

110

|

830

|

5.9

|

300~550

|

|

D

|

600

|

160

|

1200

|

8.5

|

500~850

|

|

SHJ-75

|

A

|

71

|

32-60

|

500

|

110

|

995

|

4.6

|

300~550

|

|

B

|

600

|

132

|

995

|

4.6

|

450~750

|

|

C

|

600

|

160

|

1200

|

5.5

|

500~850

|

|

D

|

600

|

250

|

1890

|

8.7

|

750~1250

|

|

SHJ-95

|

A

|

93

|

32-60

|

500

|

250

|

2260

|

4.7

|

750~1250

|

|

B

|

600

|

315

|

2380

|

5.0

|

950~1600

|

|

C

|

600

|

450

|

3400

|

7.1

|

1350~2250

|

|

D

|

600

|

550

|

4510

|

8.7

|

1650~2750

|

Why choose us

1.Energy-saving:

All main motors of machine use Variable Frequency Motor(AC), eliminating three-phase asynchronous motors;

Variable Frequency Motor:

(1) Speed regulation is easy and energy saving.

(2) AC motor has simple structure, small volume, small inertia, low cost, easy maintenance and durability.

(3) It can expand output and achieve high speed and high voltage operation.

(4) Soft start and fast brake can be achieved.

(5) No spark, explosion-proof, and strong environmental adaptability.

2.High output:

Take "PP" material as an example, the PP material is tested on the customer's site, our machines' actual production output is 10%-20% higher than the same model in the market;

3.Simple installation:

The equipment is easy to install, only need to be connected to the inlet and outlet water, which can save 2 days of installation time;

4.Advanced design:

(1)All electrical components are imported famous brands, like German "SIEMENS", France "SCHNEIDER", United States "CEME", Japan "ORMON" "TOSHIBA" "FUJI" etc.;

(2)The industry's first advanced dust cover design, beautiful appearance and simple maintenance;

(3)Use a thicker and more heat-resistant heater to ensure the heating effect of the barrel and the service life of the heater;

(4)The water cooling system of the barrel adopts stainless steel pipes and valves;

5.Others:

(1)Available production video reference;

(2)At the discretion, lead customers to visit the customer site;

6.Good after-sales service:

(1)The warranty of main gearbox is extended for free for three years;

(2)Modernized CNC processing equipment to fundamentally guarantee the supply of quantity and quality of equipment spare parts;

(3)We provide engineers overseas installation service.

.png) Contact Now

Contact Now