Product Description

Twin Screw Extruder Line Masterbatch Pelletizing Granules Extruder Machine

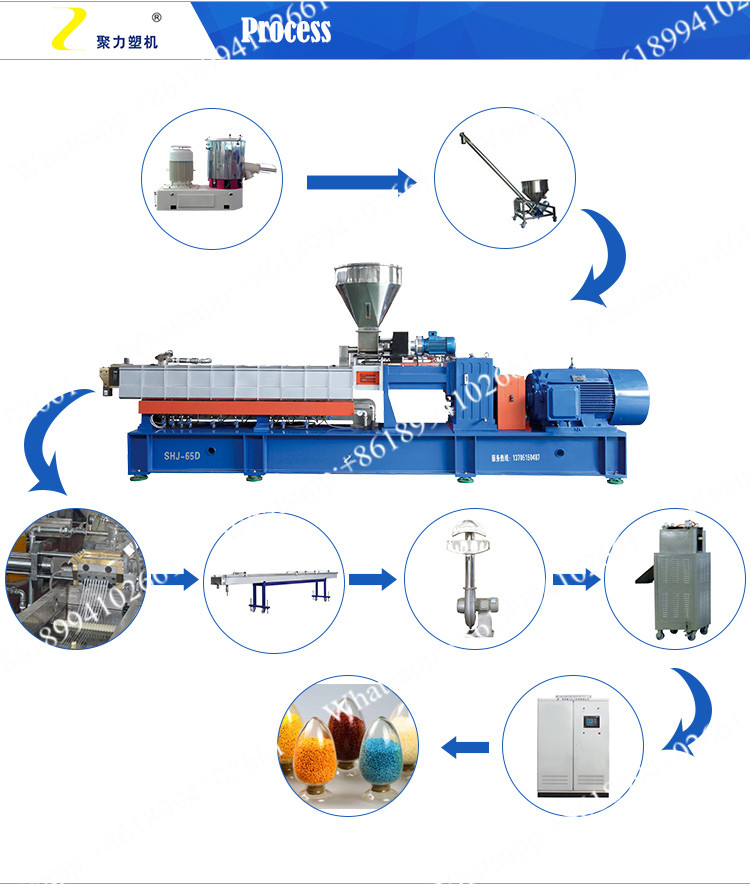

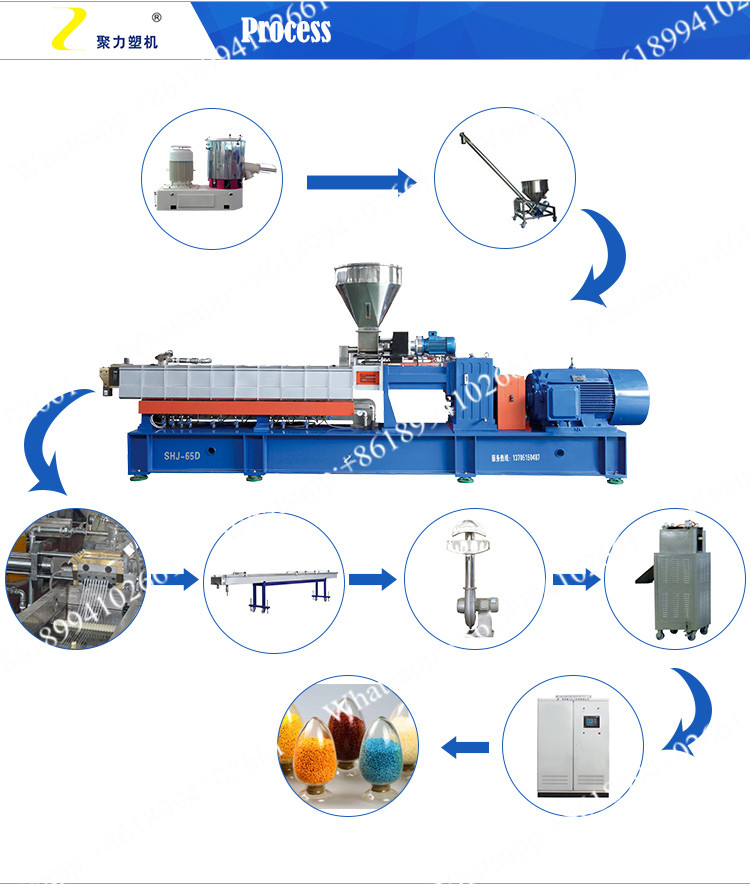

The barrel of Extruder Line Masterbatch can be opened in minutes. This makes product changeover, maintenance and research fast and easy. Both screws and barrels are designed using the building block principle. The screw configuration, barrel setup, feeding and venting, screen changing, way of pelletizing and process requirements, in consideration of the machine's versatility in other general applications.

Application of the Extruder Line Masterbatch:

--Various plastic inorganic filler, polymer blending (plastic alloy), plastic coloring, ect

--Various engineering plastic reinforcement of glass fiber, flame-retartant pellets

--Various antibacterial, insulated, toughening materials for specific uses

--Light/biology degradable film materials, amylum degradable plastics and multi-functional anti-fog film materials, etc.

--Specific material for automobiles and household appliance and cable materials, etc

--Themoplastic elastomers, such as TPR, TPE, and SBS, etc

--Regenerate pellets for PVC airproof pieces, thermo-soluble glue, etc

Twin Screw Co-rotating Extruder Advantages

1. simple process

2. automatic temperature control

3. low power consumption

4. non-pollution

5. high capacity

FAQ

Q1: Are you a factory or trading company ? How is you factory extrusion experience?

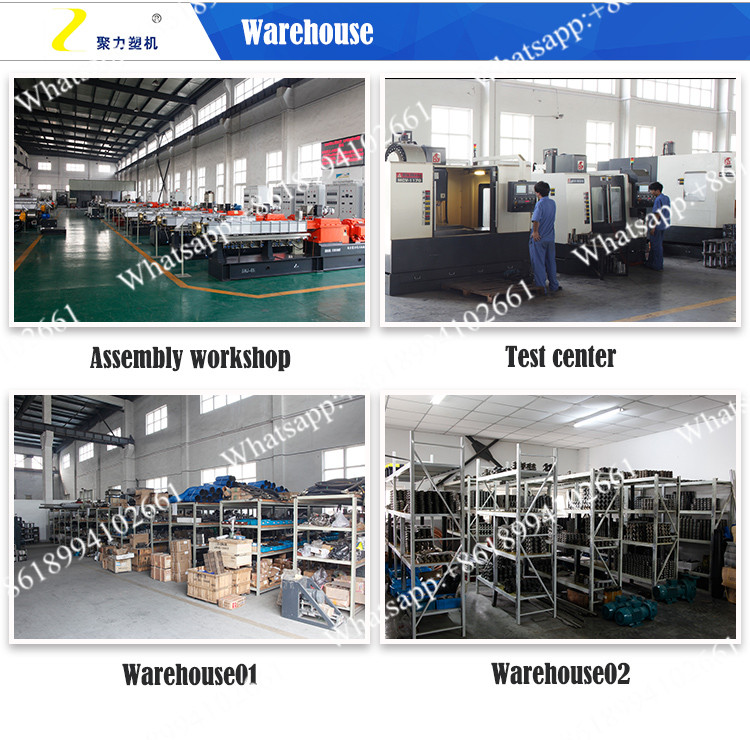

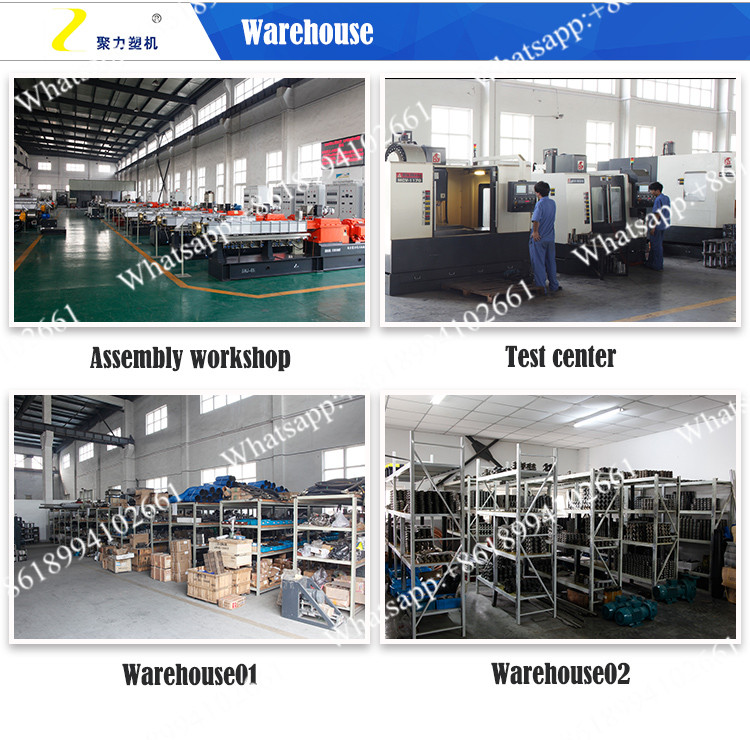

A: We are factory in Nanjing , 20 years experience on extrusion.Leading supplier in Nanjing city.

Q2:Where is your factory located? How can I visit there?

A : Our factory is based in 77 Tangtong Rd,Hushu,Jiangning District Nanjing , Jiangsu Province, China,

1) You can fly to Nanjing Lukou Airport or you can fly to Shanghai then take high-speed train to Nanjing South Railway Station.

2) We will arrange the pick up in Nanjing Lukou airport or South Railway Station

Q3:What can you provide for after sale service?

A:We can send engineers to your factory for installation and training if customers‘ required

Q4:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q5:Could you afford technician team to guide ours installation and commissioning?

A:Experience engineer oversea installation service provided.

.png) Contact Now

Contact Now