Product Description

New design Parallel Twin Screw Extruder

USE: This extruder is most suitable for the production of engineering plastic, plastic with fiber

Double screw extruder features:

The barrel and screw is of building block type, full intermeshing type screw is easy to clean. The screws are able to arrange according to the different plastic material, has the advantages of interchangeability, strong adaptability, good mixing, plasticization and exhaust.

1.The material of the screw can be 38CrMoALA, under nitridation treatment; or made of alloy bushing which is anti-wear. The heating of barrel is by cast aluminum, cooled by water.

2.The motor can be DC motor, equipped with silicon controlled speed regulator or British Eurotherm 590 speed regulator; or AC motor frequency speed regulator. The temperature controller is Japan RKC brand or China famous brand.

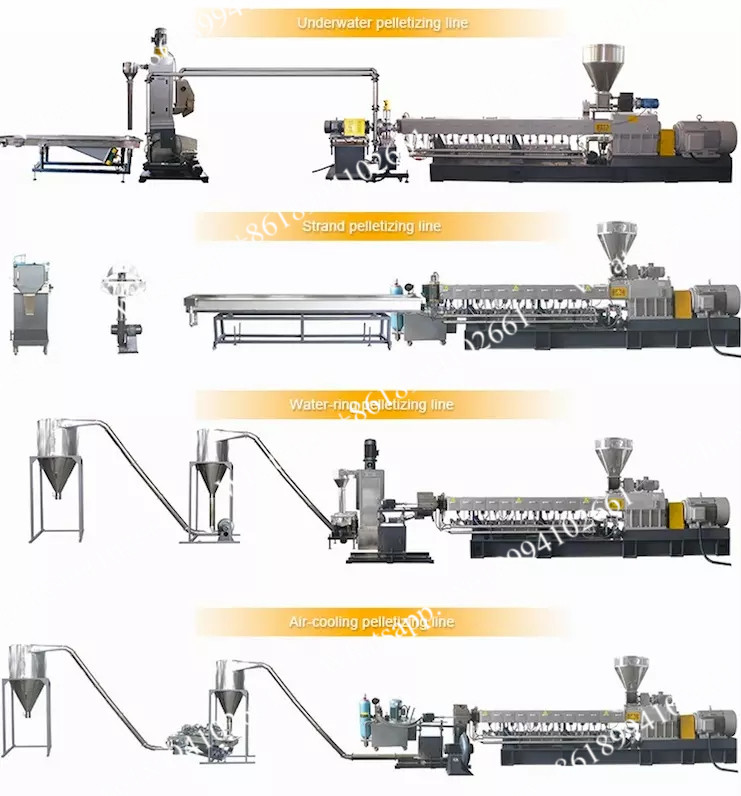

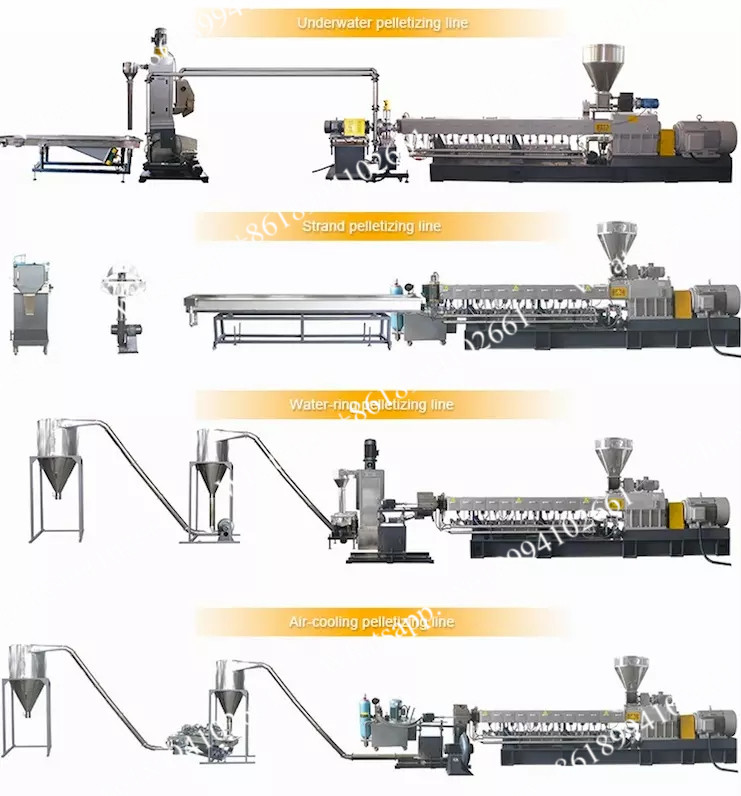

1.Strand Extruders for

Filling/Compounding and Reinforcing

Fibre reiforcement : glass fibre, carbon fibre reinforced PP, PA,

PBT, ABS, PC, POM, PPS, PET, etc.

Fibre reiforcement : glass fibre, carbon fibre reinforced PP, PA, PBT, ABS, PC,

POM, PPS, PET, etc.

Incorporation of Fillers: Caco3, Talc, TiO2, carbon black,filled PE, PP, or

EVA, etc.

Cable Compounds: cable sheath, cable insulation compounds of LDPE, HDPE, LLDPE,

MDPE; radiation-crosslinkable compounds, optical fibre protection compounds,

heat-shrinkable polymer compounds.

Special Compounds: PPR pipe compounds, PE compounds for crosslinked pipes,

tobacco filter compounds, etc.

High Concentration Color Masterbatches: PE, ABS, PS, EVA, PP,etc. with high

concentration of pigments and other processing aids.

Masterbatches with Flame-retardants: PE, ABS, PS, EVA, PET, PP, etc. with flame

retardants and other additives.

The twin screw strand extruder also fit for PET bottles/

flakes recycling.

2. Water Ring Extruders for

Filiing/Compounding/Modificating

PE, EVA etc. Filled with CACO3,talc,TIO2,carbon black etc.

Cable sheath, cable insulation compoundes of LDPE,HDPE,LLDPE,or

MDPE;

Radiation-crosslinkable, heat-shrinkable cable compounds;

TPR, TPU thermoplastic elastomers; EVA and hot-melt adhesives;

Color concentrations of PE,ABS, PS,EVA,etc;

Flame retardant master batches of ABS,PS,EVA,etc;

Master batches with PE,PP,PS,etc carriers for degradation

applications.

3.Air-cooling Extruders

Enforcing modification:PE,EVA etc.+CaCo3,Talc, TiO2,Carbon black.

Degradable master batch: PE,PS etc.+starch,additive etc.

Anti-flame master batch: PE, EVA etc.+Sb2O3, Mg(OH)2,AI2(OH)3 etc.

4. Underwater Extruders

1.The main material is PE+CaCO3

2.The metering feeders are equipped with single screw, twin screw,

hollow screw, forced feeding ,side-feeding, etc

3.Different requirementsof feeding, such as power, pellet, lump

and luqid material.

Pre-sales service:

• Introducing in detail features and application of the

products to customer

• Selecting rconomical and practical machine&equipment

for customer

• Providing operation data of the related

machine&equipment

• Providing means of trial performance for customer

Sales service:

• Recommending engineering conditions required for installation

of the machine&equipment

• Communication in time the manufacturing progress of the

machine with user

• Providing assistance in technical conditions,screw

combination and barrel disposition needed for product

After-sales service:

• Providing on-the-spot technical assistance in

installation,commissioning and training

• Filling in detail customer's information

• Providing long-term maintenance service and spare parts

.png) Contact Now

Contact Now