Product Description

The SHJ series twin-screw extruders hasve screw threads made of high grade steel with a five-axis machining tool to reduce clearance and wear.

This twin screw extruder is equipped with PLC controllers and high-level touch screen panels for manual or automatic operations. The extruder’s operating parameters are input and displayed on the touch panel. Designed by CAD, the closely intermeshed screw elements have excellent self-wiping characteristics, and can be interchanged with each other easily. Besides, twin-screw compounding extruder is installed with the newly designed torque distribution system, high-precision grinding of hardened gear teeth, and imported high-quality key bearings.

Furthermore, the system is capable of remote control. This twin screw extruder can be extensively used in many fields, such as polymer blending, homogeneity, plasticization, filling modification and granulation, engineering polymer and glass fiber reinforcement, master batch, functional parent granule, special material, power coating material and cable material reactive extrusion, degassing and devolatilization, etc.

All SHJ series twin-screw compounding extruders meet or exceed CE and international safety standards. Juli extruder can also design an entire twin screw extruder production line to meet customers’ specifications

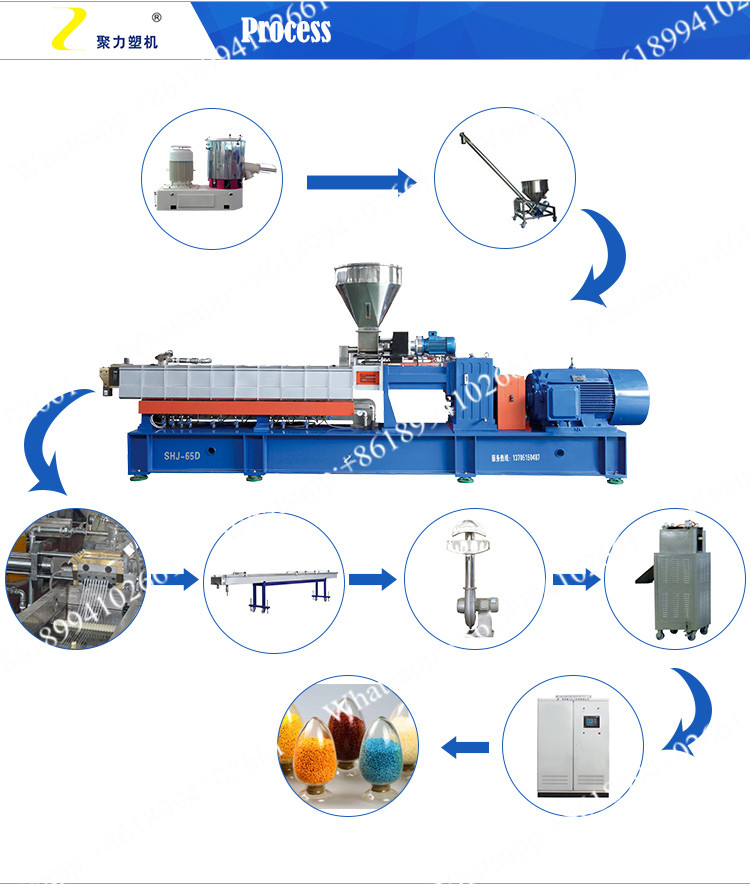

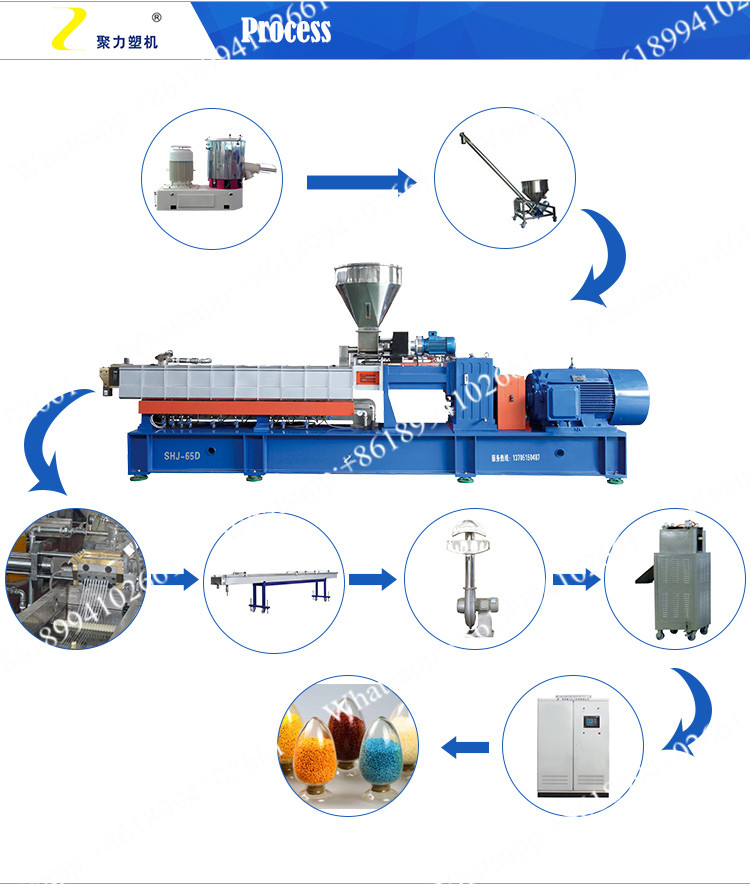

Plastic pelletizing line Process flow:

Conveying feeding→metal detector → parallel twin screw extruder → bipolar vacuum exhaust system → hydralic screen exchanger → material outing mould → water tank → drying system → cutting granulating unit → storage hopper

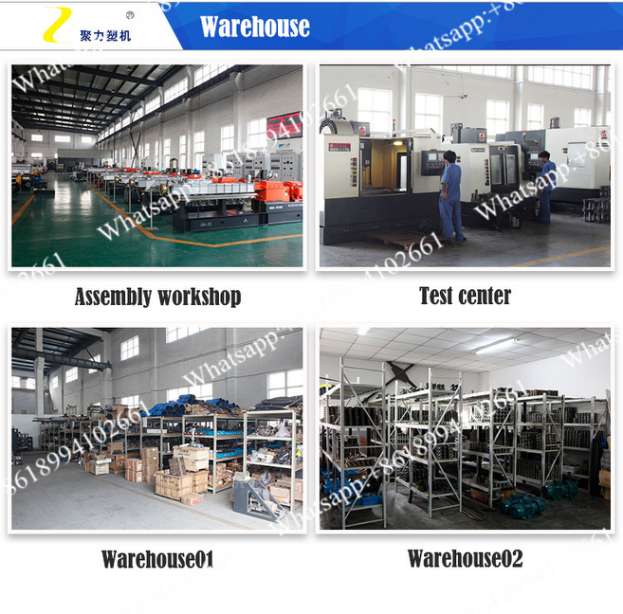

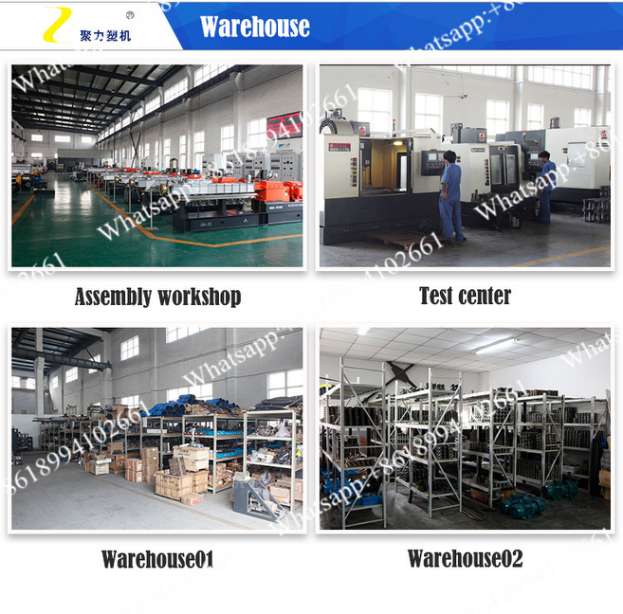

Description of Granules Extruder Machinery Plant:

Parallel twin screw extruderis a highly efficient mixing,

extruding equipment. Its core section is composed of

"00"type barrel and two screws, which mesh with each other. It also

has driving system and control system, feeding system to form a kind of special

extruding, granulation and shaping processing equipment.

The screw stem and barrel adopt building type design principle to

change the length of the barrel, choose different screw stem parts to assemble

the line according to material characteristics, so as to get the best work

condition and max function.

Because Parallel twin screw extruder has good mixing, separating,

dewatering and self-cleaning functions to avoid the materials wrapping the

axle, caking in the extruding process. With the rotation of the screw, the

surface of the materials continuously change, helps the volatile matter

dewater, treat, and etc.

Main advantage of Granules Extruder Machinery Plant:

1.Inverted rotation double-screw stem makes the material flow in

shape. This can meet the technique demands of transport, compression, mixture

and refining, exhaust, plasticizing of the material.

2.The special oil heating system in the core of the screw stem can

ensure the relative stability of the product quality.

3.Different models of screw stems of the machine are designed to

match the relevant auxiliary machine to produce all kinds of pipe material,

shaped material, grains and others.

4.Parallel twin screw extruder has advantages of advanced design,

compact structure, excellent characteristics, beautiful appearance, steady

operation, low energy consumption, high output and long use life.

|

Underwater

pelletizing system

|

Pelletizer for the production of almost all thermoplastics, hot

melt adhesives,

especially for some low hardness and high viscosity materials

|

|

Strand

pelletizing system

|

Pelletizer for the processing of the melted polymer to cylindrical,

dry and easy to handle plastics pellets

|

|

Water ring

pelletizing system

|

Pelletizer for the production of various masterbatch,

filled and reinforced products etc.

|

|

Air cooling

pelletizing system

|

Pelletizer for the production of temperature and shear-sensitive plastics

|

FAQ

Q1: Are you a factory or trading company ? How is you factory

extrusion experience?

A: We are factory in Nanjing , 20 years experience on

extrusion.Leading supplier in Nanjing city.

Q2:Where is your factory located? How can I visit

there?

A : Our factory is based

in 77 Tangtong Rd,Hushu,Jiangning District Nanjing

, Jiangsu Province, China,

1) You can fly to Nanjing Lukou

Airport or you can fly to Shanghai then take high-speed train to Nanjing

South Railway Station.

2) We will arrange the pick up in

Nanjing Lukou airport or South Railway Station

Q3:What can

you provide for after sale service?

A:We can send engineers to your factory for

installation and training if customers‘ required

Q4:If we have very special request for the production

line,could you help me to do the design?

A:Experienced mechanical designer

customized-design provided.

Q5:Could you afford technician team to guide ours

installation and commissioning?

A:Experience engineer oversea installation

service provided.

Q6: Why choose you ?

A: 1)

Quick response. Once we got the inquiries from you, we will reply you

within 12hours.

2) Promising leading time. To guarantee the quality, the machine will be

finished within max 20days.

3) Before leaving factory, all the machine will be fully tested.

4) Customized package(Wooden) will ensure a safety shipping.

.png) Contact Now

Contact Now