Product Description

The machine is optionally operated (alternative in PC touch pan el or PLC control system accompanied with Human Machine interface) with all technical parameters regulated on touch screen. Stirring paddle and cutter adopt frequency speed regulation. The granule diameter can be controlled easily. Rotating shaft clearance is full of Compressed air, which prevents the rotating shaft from the dust of material, and the machine has auto-cleaning function.Conical material chute makes the material mix uniformly, cooling temperature of interlayer jacket can be controlled automatically, that improving quality of granule. Pot lid lift automatically, discharge mouth can be equipped with drying equipment.

|

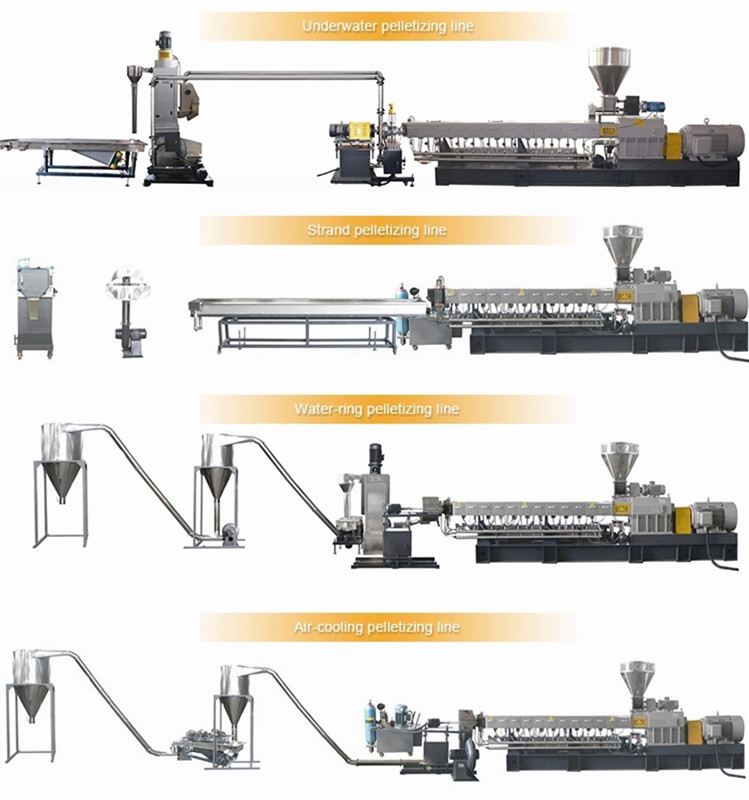

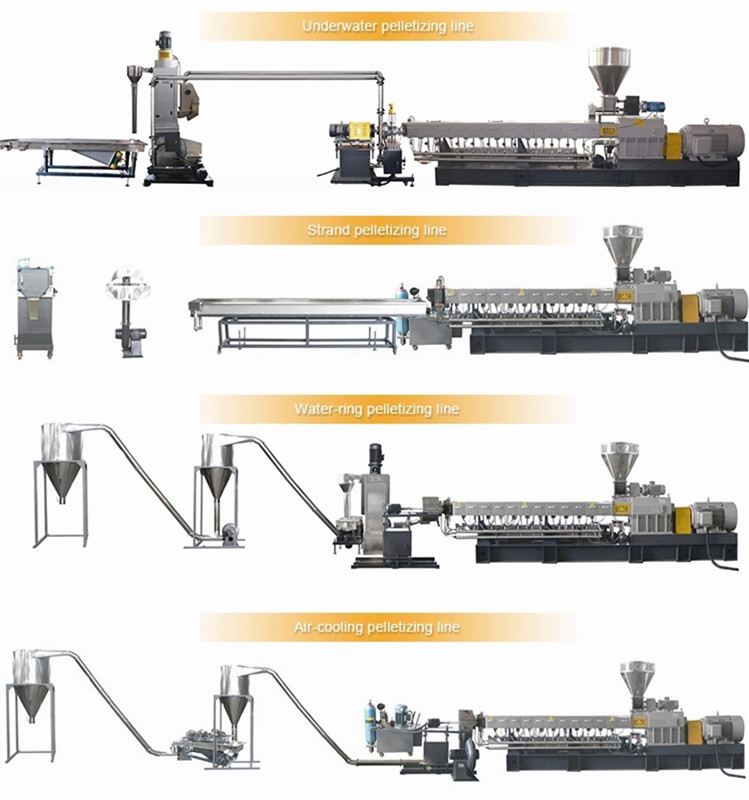

Underwater

pelletizing system

|

Pelletizer for the production of almost all thermoplastics, hot melt adhesives,

especially for some low hardness and high viscosity materials

|

|

Strand

pelletizing system

|

Pelletizer for the processing of the melted polymer to cylindrical,

dry and easy to handle plastics pellets

|

|

Water ring

pelletizing system

|

Pelletizer for the production of various masterbatch,

filled and reinforced products etc.

|

|

Air cooling

pelletizing system

|

Pelletizer for the production of temperature and shear-sensitive plastics

|

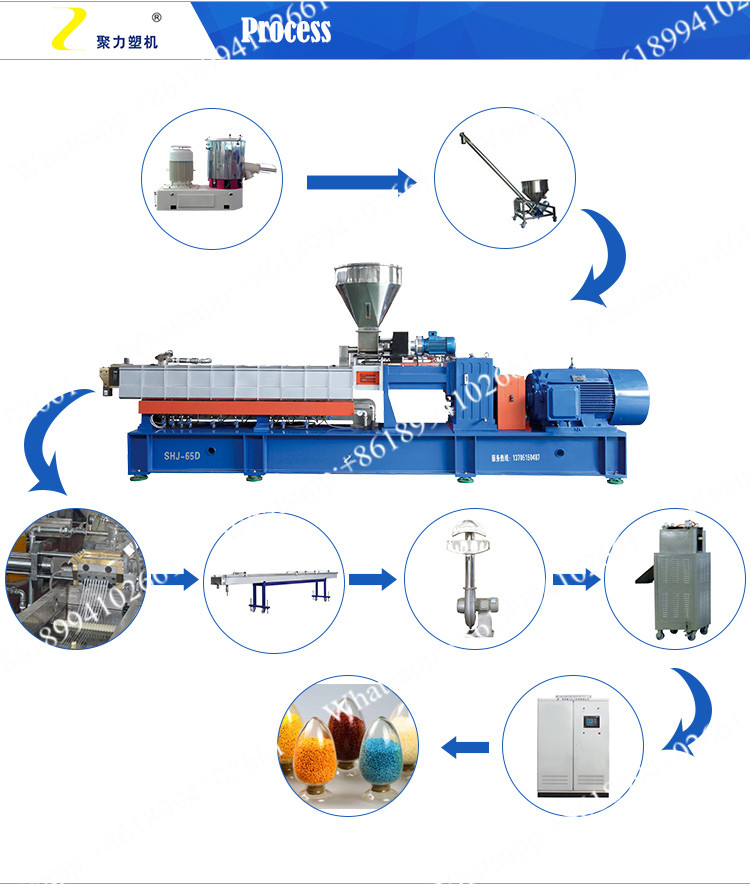

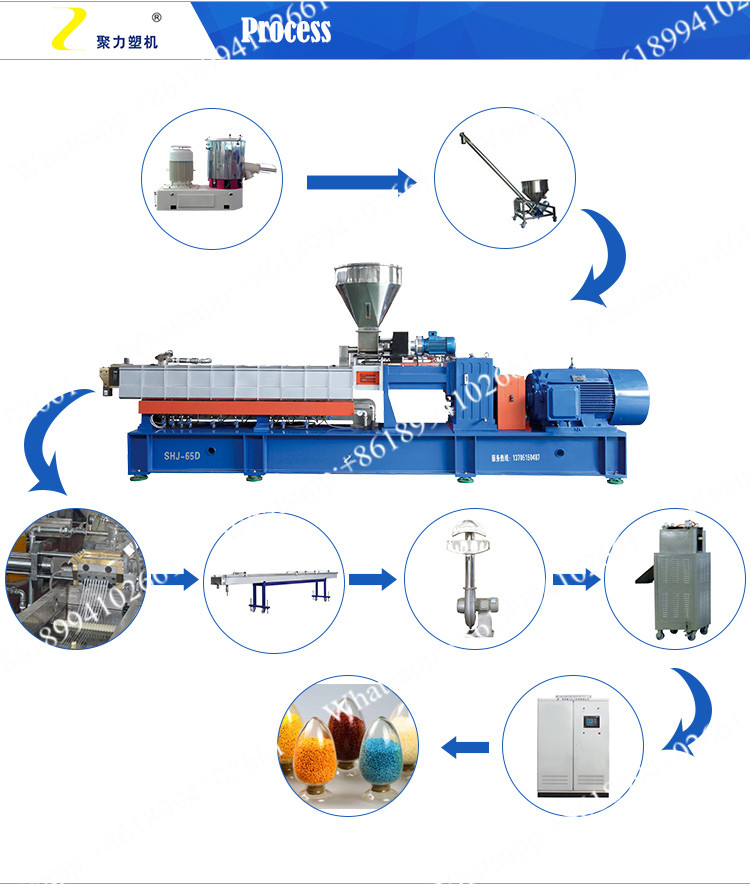

Main advantage of Granules Extruder Machinery Plant:

1.Inverted rotation double-screw stem makes the material flow in shape. This can meet the technique demands of transport, compression, mixture and refining, exhaust, plasticizing of the material.

2.The special oil heating system in the core of the screw stem can ensure the relative stability of the product quality.

3.Different models of screw stems of the machine are designed to match the relevant auxiliary machine to produce all kinds of pipe material, shaped material, grains and others.

4.Parallel twin Screw Extruder has advantages of advanced design, compact structure, excellent characteristics, beautiful appearance, steady operation, low energy consumprion, high output and long use life.

Before-sale

1. Introduce products and applications detain

2. Recommend suitable solution

3. Provide with reference in formation

4. Offer lab for test

During manufacturing

1. Provide with layout and engineering conditions

2. Inform the project processing status

3. Offer other documents

After-sale

1. Provide with installation ,commissioning and training

3. Offer spare parts

4. Provide with technical support

5. Visit customer regularly and correct information

.png) Contact Now

Contact Now