Product Description

1,Optimization of the particle shape, more smooth, uniform particles, such as water droplets or spherical

2,High particle density, good liquidity

3,Prevent oxidation of the granules

4,Less bonding phenomenon

5,More convenient operation; production and operating experience

6,A key to boot, automatic continuous production

7,Superhard alloy die two years warranty

8,Without sharpening the blade without replacement within a year and polished

9,Shorten the curing /solidify time, less space and cooling water demand

10.Full closed production. Environment friendly

11,low noise, no dull pollution

|

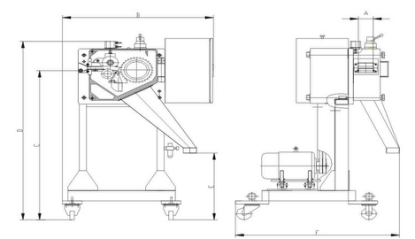

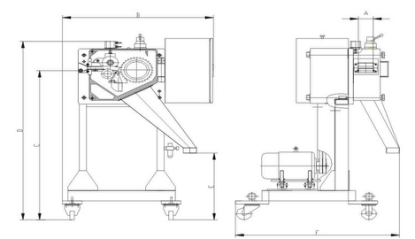

Model:

|

LQ-500

|

|

Maximum output kg/h:

|

500

|

|

cutting grain number (piece):

|

26

|

|

Maximum draft line speed m/min:

|

96

|

|

cutting grain size mm:

|

3×3

|

|

Rated torque Nm:

|

36.1

|

|

Rubber roll size D×L(mm):

|

100*200

|

|

Rotor size D×L(mm):

|

200*200

|

|

the teeth number of rotor Z

|

32

|

|

Fixed blade size a×b×h mm

|

200*15*30

|

|

motor power capacity kw

|

5.5-7.5

|

Characteristics of the plastic pelletizer/cutter/granulator machine

♦High quality & reasonable price

♦Low noise

♦Easy operation

♦Available for various plastic raw material, like PP, PA, PBT , ABS, AS, PC, POM, PPS, PET, etc.

♦Produced as customer required

♦Motor can be controlled by Frequent Inverter control to meet customer productivity demand.

♦suitable for different pelletizing line.

FAQ

Q1: Are you a factory or trading company ? How is you factory extrusion experience?

A: We are factory in Nanjing , 20 years experience on extrusion.Leading supplier in Nanjing city.

Q2:Where is your factory located? How can I visit there?

A : Our factory is based in 77 Tangtong Rd,Hushu,Jiangning District Nanjing , Jiangsu Province, China,

1) You can fly to Nanjing Lukou Airport or you can fly to Shanghai then take high-speed train to Nanjing South Railway Station.

2) We will arrange the pick up in Nanjing Lukou airport or South Railway Station

Q3:What can you provide for after sale service?

A:We can send engineers to your factory for installation and training if customers‘ required

Q4:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q5:Could you afford technician team to guide ours installation and commissioning?

A:Experience engineer oversea installation service provided.

Q6: Why choose you ?

A: 1) Quick response. Once we got the inquiries from you, we will reply you within 12hours.

2) Promising leading time. To guarantee the quality, the machine will be finished within max 20days.

3) Before leaving factory, all the machine will be fully tested.

4) Customized package(Wooden) will ensure a safety shipping.

Presales service:

>Introducing in detail features and application of the products to customer

>Selecting economical and practical machine & equipment for customer

>Providing operation data of the related machine & equipment

>Providing means of trial performance for customer

Sales service:

>Recommending engineering conditions required for installation of the machine & equipment

>Communicating in time the manufacturing progress of the machine with user

>Providing assistance in technical conditions, screw combination and barrel disposition needed for product

After-sales service:

>Providing on-the-spot technical assistance in installation, commission and training

>Filling in detail customer’s information

>Providing long-term maintenance service and spare parts

>Giving technical support to customer for developing new product

>Providing free maintenance for a year.

.png) Contact Now

Contact Now