Product Description

1.Eruo-style rectangle barrel, reflux refrigeration is optimized and disposed ,which makes temperature difference in D areas smaller.

2.Innovated design of heater tightened style insures high efficiencey of heat transfer and long operation life.

3.The material of cylinder can use high quality nitrided steel, corrosion proof or antifriction with corresponding prcess.

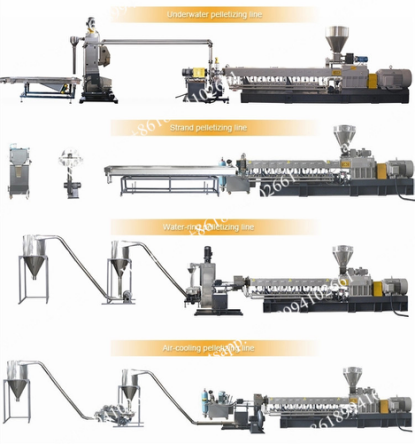

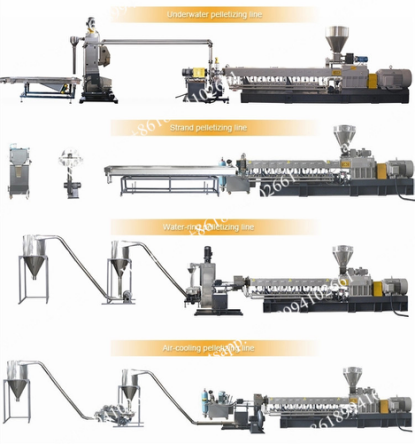

4.Various modes of pelletizing, such as water-cooling strand,air-cooling pelletizing, water-ring pelleitizing, under water pelletizing.etc.

5.The screw is made of high tool steel 38 CrMoALA or W6Mo5Cr4V2 and can fulfill efficient self-cleaning, transmission,compounding ,pressure-forming,etc.

6.Various metering feeders and new-style gear transmission system.

1.Energy-saving:

All main motors of machine use Variable Frequency Motor(AC), eliminating three-phase asynchronous motors;

Variable Frequency Motor:

(1) Speed regulation is easy and energy saving.

(2) AC motor has simple structure, small volume, small inertia, low cost, easy maintenance and durability.

(3) It can expand output and achieve high speed and high voltage operation.

(4) Soft start and fast brake can be achieved.

(5) No spark, explosion-proof, and strong environmental adaptability.

2.High output:

Take "PP" material as an example, the PP material is tested on the customer's site, our machines' actual production output is 10%-20% higher than the same model in the market;

3.Simple installation:

The equipment is easy to install, only need to be connected to the inlet and outlet water, which can save 2 days of installation time;

4.Advanced design:

(1)All electrical components are imported famous brands, like German "SIEMENS", France "SCHNEIDER", United States "CEME", Japan "ORMON" "TOSHIBA" "FUJI" etc.;

(2)The industry's first advanced dust cover design, beautiful appearance and simple maintenance;

(3)Use a thicker and more heat-resistant heater to ensure the heating effect of the barrel and the service life of the heater;

.png) Contact Now

Contact Now