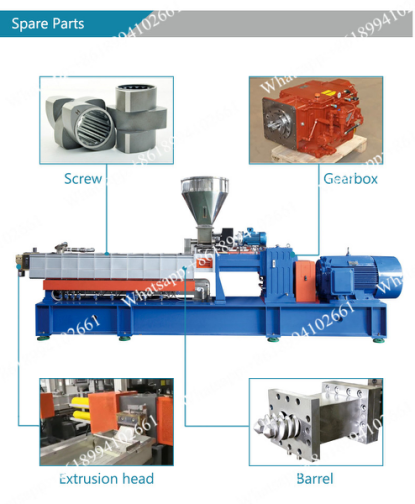

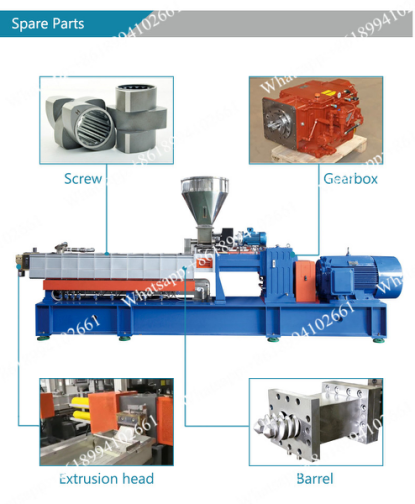

Product Description

twin screw extruder transmission gearbox for machine pellet prices

SHJ

series gearbox utilizes state of the art precision standard ISO of

cylindrical gear of involute spline, combining our long term experience

with the application of twin-screw extruder.SHG series gearbox was

highly engineered for co-rotating twin screw extruders, with entirely

indepent intellectual peoperty rights.

Gearbox Features

|

adopt special tooth grinding software to trim the gear to achieve high gear strength;

|

|

gear tooth load equally distributed;

|

|

different speed reduce ratio-2.5,3,3.75, better for plastic processing

|

|

reduced vibration, low noise as it is made between 60-65 decibels;

|

|

multi optimization ro rhe gearbox internal structure according to check calculation

|

|

unique gear data and mechanism;

|

|

external oil lubrication system convenient to maintain

|

|

piping heat exchanger with large cooling area, say 2.6m2

|

twin screw extruder transmission gearbox for machine pellet prices

SHJ series gearbox utilizes state of the art precision standard ISO of cylindrical gear of involute spline, combining our long term experience with the application of twin-screw extruder.SHG series gearbox was highly engineered for co-rotating twin screw extruders, with entirely indepent intellectual peoperty rights.

Key Features

1.Highest gearbox structure strength ensures minimum rotation vibration

2.High torque and high output speed rate design

3.Precision gear grinding to keep operation noise very low

4.Forced lubrication and cooling filter system to ensure excellent heat dissipation

5.All bearings are sourced from global recognized brands

Work blank

Select high quality and hardness of ductile iron material.

Rough machining

Many sets of rough machining equipment, such as Gantry-type milling, radial drill, etc.,

Realized the blank shape and the inner hole of rough machining.

finish machining

Many sets of finishing equipment, such as CNC Grinding Machine, NC Boring Machine ,etc.,

Further processing of each working procedure, the accuracy is higher, only you.

Gearbox Inspection

High-end testing equipment and instruments, professional inspection team, the gearbox shape, center distance, inner hole and into the next procedure, after inspection and correct.

Assemble

Strong assembly and r&d team, the parts will be assembled according to the drawing, step by step audit, by running test after product finished.

Delivery

Export standard packing, packaging, use at the bottom of the fixed plate, ensure that the product does not shift in transit.

FAQ

Q1: Are you a factory or trading company ? How is you factory extrusion experience?

A: We are factory in Nanjing , 20 years experience on extrusion. Leading supplier in Nanjing city.

Q2:Where is your factory located? How can I visit there?

A : Our factory is based in 77 Tangtong Rd,Hushu,Jiangning District Nanjing , Jiangsu Province, China,

1) You can fly to Nanjing Lukou Airport or you can fly to Shanghai then take high-speed train to Nanjing South Railway Station.

2) We will arrange the pick up in Nanjing Lukou airport or South Railway Station

Q3:What can you provide for after sale service?

A:We can send engineers to your factory for installation and training if customers‘ required

Q4:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q5:Could you afford technician team to guide ours installation and commissioning?

A:Experience engineer oversea installation service provided.

Q6: Why choose you ?

A: 1) Quick response. Once we got the inquiries from you, we will reply you within 12hours.

2) Promising leading time. To guarantee the quality, the machine will be finished within max 20days.

3) Before leaving factory, all the machine will be fully tested.

.png) Contact Now

Contact Now