Product Description

In the production process, the use of the loss in weight feeder /weighing system will be more help to processing the product. The weighing system/loss in weight can be accurately weighed out the required amount of and automatic feeding. The use of the loss in weight feeder/weighing system can save your time and manpower. In order to ensure the precision of the weighing system/loss in weight feeder, the loss in weight feeder/weighing system need to be checked twice a week after putting in use. If you want to know more about the loss in weight feeder/weighing system, please contact us and we will introduce the weighing system/loss in weight feeder in detail.

It is a continuous loss-in-weight gravimetric dosing system for various viscosity liquid additives, which is applied to handling plastic pellets in compounding and extrusion processes. loss-in-weight gravimetric feeder provides constant and accurate processing thanks to a suitable dosing pump, an advanced weighing system and sophisticated software.

Features:

• Modular design, safe, simple, and reliable use

• Components: LFE feeder pump module, LVH weighing hopper, LSP weighing module, EC-LWL control module

• Operation and display through Sonner M250 industrial computer

• Capacity: 1 to 200 L / h

• Accuracy: ± 0.1 to 0.25 %

Applications:

• Processes: polymer compounding (polyolefins modification, engineering plastics, polymer alloys, masterbatch, composites), plastics extrusion (cable), food processing

• Handled material: liquids

Accessories:

• Refilling hopper module: 40 L / 80 L stainless steel hopper Stainless steel hopper lid Inlet / filter type dust outlet Silicon sealing parts

• IEVD32 refilling electrical valve: Stainless steel body and surface, plating treatment Stainless steel gate

• Inlet / outlet soft connector

• Standard installing frame

• Heater parts to heat up solidfied liquids at ambient temperature

FAQ

Q1: Are you a factory or trading company ? How is you factory extrusion experience?

A: We are factory in Nanjing , 20 years experience on extrusion.Leading supplier in Nanjing city.

Q2:Where is your factory located? How can I visit there?

A : Our factory is based in 77 Tangtong Rd,Hushu,Jiangning District Nanjing , Jiangsu Province, China,

1) You can fly to Nanjing Lukou Airport or you can fly to Shanghai then take high-speed train to Nanjing South Railway Station.

2) We will arrange the pick up in Nanjing Lukou airport or South Railway Station

Q3:What can you provide for after sale service?

A:We can send engineers to your factory for installation and training if customers‘ required

Q4:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q5:Could you afford technician team to guide ours installation and commissioning?

A:Experience engineer oversea installation service provided.

Q6: Why choose you ?

A: 1) Quick response. Once we got the inquiries from you, we will reply you within 12hours.

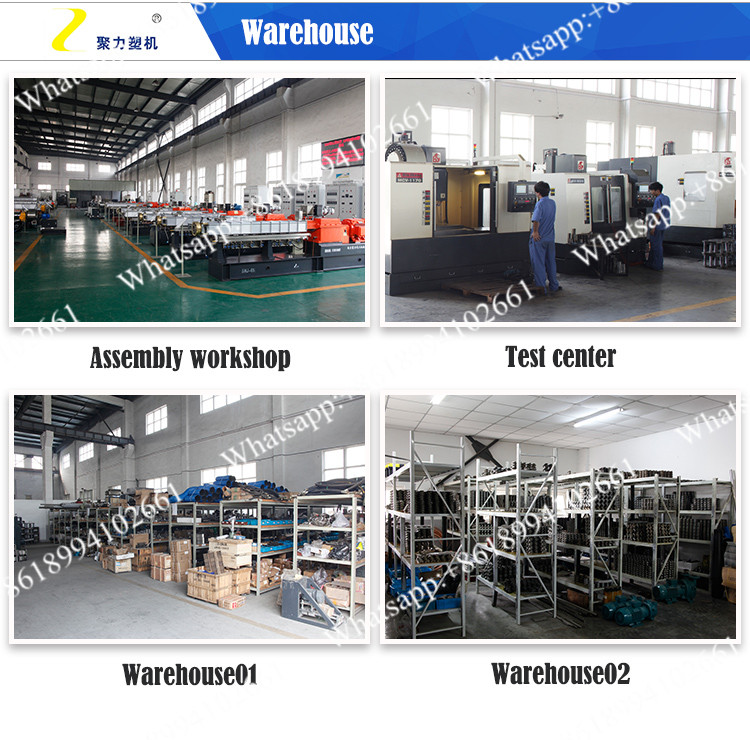

2) Promising leading time. To guarantee the quality, the machine will be finished within max 20days.

3) Before leaving factory, all the machine will be fully tested.

4) Customized package(Wooden) will ensure a safety shipping.

.png) Contact Now

Contact Now