Product Description

Plastic Color Masterbatch Pelletizing Production Line :

1.Screw components designed by computer aids is kneading type, has excellent self-cleaning function, the new kneading block design effectively avoid the problems of overheating and energy consumption.

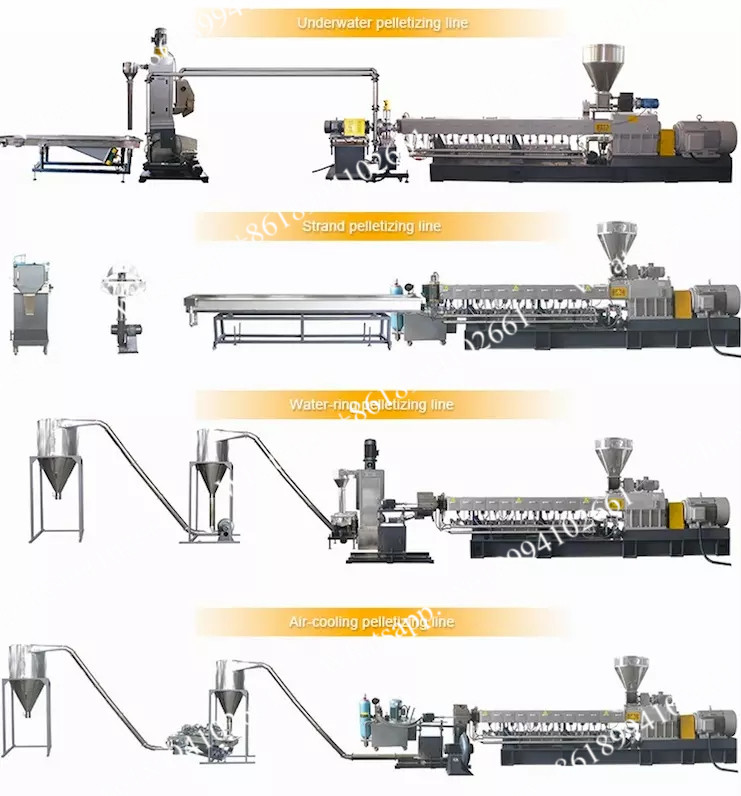

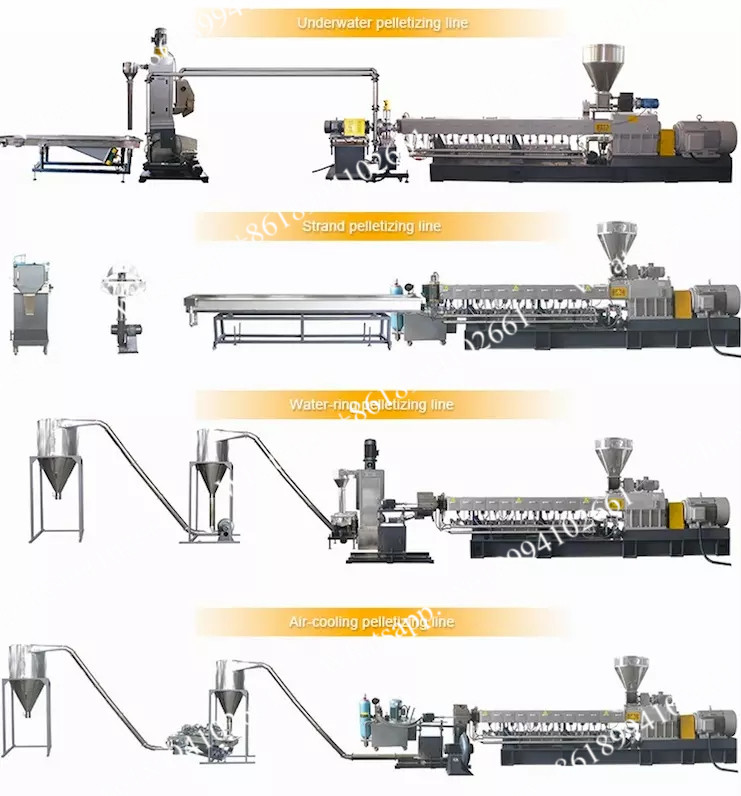

2. According to process system and formula requirements, the unit can optimize its L/D ratio, barrel structure, screw array, venting number and location, feeding method, electrical control methods etc. for rational allocation.

3. Granulation system: water-cooling strand pelletizing, air-cooling die face hot cutting, water ring die face hot cutting, Eccentric water mist hot cutting, water and underwater die face hot cutting and so on.

1.Strand Extruders for

Filling/Compounding and Reinforcing

Fibre reiforcement : glass fibre, carbon fibre reinforced PP, PA,

PBT, ABS, PC, POM, PPS, PET, etc.

Fibre reiforcement : glass fibre, carbon fibre reinforced PP, PA, PBT, ABS, PC,

POM, PPS, PET, etc.

Incorporation of Fillers: Caco3, Talc, TiO2, carbon black,filled PE, PP, or

EVA, etc.

Cable Compounds: cable sheath, cable insulation compounds of LDPE, HDPE, LLDPE,

MDPE; radiation-crosslinkable compounds, optical fibre protection compounds,

heat-shrinkable polymer compounds.

Special Compounds: PPR pipe compounds, PE compounds for crosslinked pipes,

tobacco filter compounds, etc.

High Concentration Color Masterbatches: PE, ABS, PS, EVA, PP,etc. with high

concentration of pigments and other processing aids.

Masterbatches with Flame-retardants: PE, ABS, PS, EVA, PET, PP, etc. with flame

retardants and other additives.

The twin screw strand extruder also fit for PET bottles/

flakes recycling.

2. Water Ring Extruders for

Filiing/Compounding/Modificating

PE, EVA etc. Filled with CACO3,talc,TIO2,carbon black etc.

Cable sheath, cable insulation compoundes of LDPE,HDPE,LLDPE,or

MDPE;

Radiation-crosslinkable, heat-shrinkable cable compounds;

TPR, TPU thermoplastic elastomers; EVA and hot-melt adhesives;

Color concentrations of PE,ABS, PS,EVA,etc;

Flame retardant master batches of ABS,PS,EVA,etc;

Master batches with PE,PP,PS,etc carriers for degradation

applications.

3.Air-cooling Extruders

Enforcing modification:PE,EVA etc.+CaCo3,Talc, TiO2,Carbon black.

Degradable master batch: PE,PS etc.+starch,additive etc.

Anti-flame master batch: PE, EVA etc.+Sb2O3, Mg(OH)2,AI2(OH)3 etc.

4. Underwater Extruders

1.The main material is PE+CaCO3

2.The metering feeders are equipped with single screw, twin screw,

hollow screw, forced feeding ,side-feeding, etc

3.Different requirementsof feeding, such as power, pellet, lump

and luqid material.

Pre-sales service:

• Introducing in detail features and application of the

products to customer

• Selecting rconomical and practical machine&equipment

for customer

• Providing operation data of the related

machine&equipment

• Providing means of trial performance for customer

Sales service:

• Recommending engineering conditions required for installation

of the machine&equipment

• Communication in time the manufacturing progress of the

machine with user

• Providing assistance in technical conditions,screw

combination and barrel disposition needed for product

After-sales service:

• Providing on-the-spot technical assistance in

installation,commissioning and training

• Filling in detail customer's information

• Providing long-term maintenance service and spare parts

.png) Contact Now

Contact Now