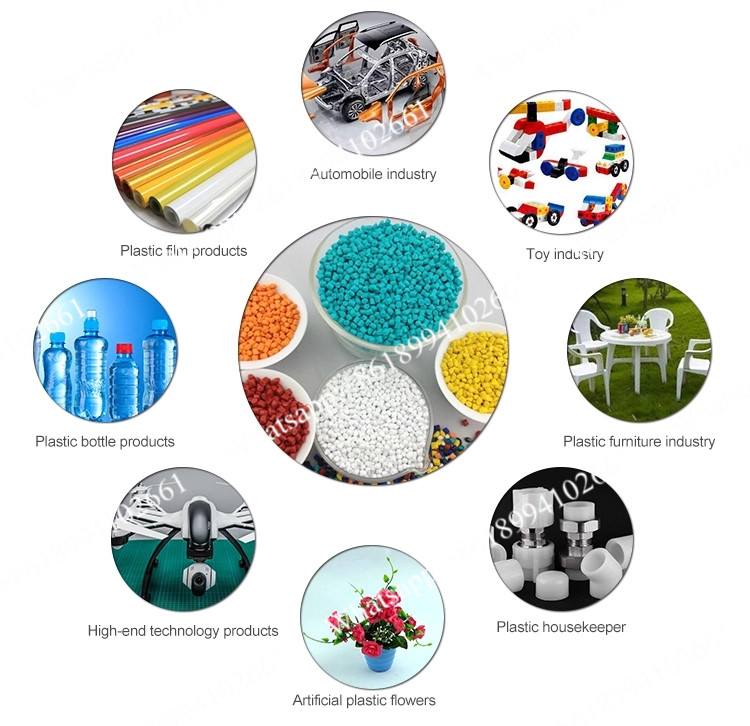

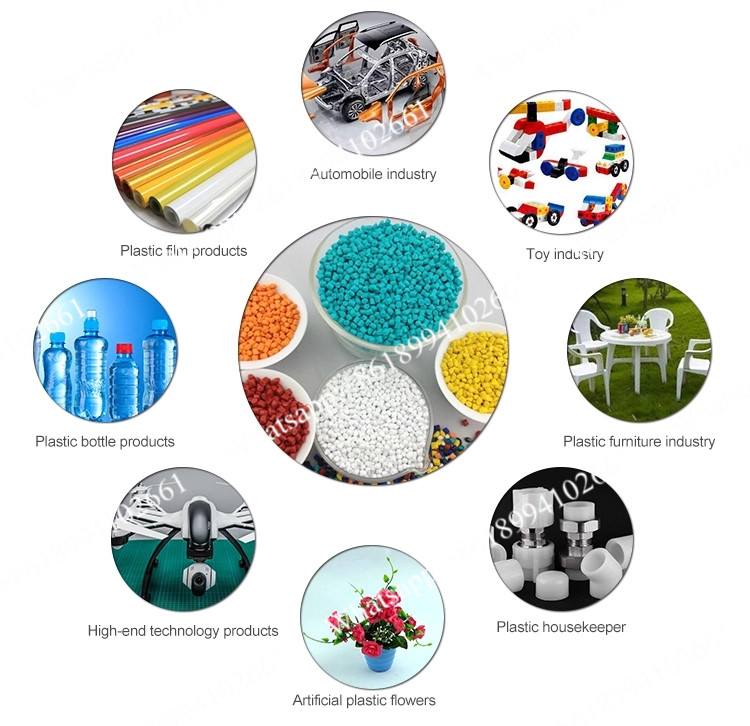

Product Description

High Filler Masterbatch is made of talc, calcium carbonate, kaolin and other inorganic powder compounding with resin and lubricants through twin-screw pelletization.It is widely used in polyethylene, polypropylene, polyvinyl chloride,

polyester, ABS, PS, EVA blown barrels, pipes, wire series, films, strapping, injection molding, extrusion and so on. High

Filler Masterbatch has these properties:enhanced,incremental,reduce costs,improve heat resistance,low-carbon

environment.

High Filler Masterbatch can be divided into: PP calcium carbonate filler, PE calcium carbonate filler, talc filler,

transparent filler

|

Underwater

pelletizing system

|

Pelletizer for the production of almost all thermoplastics, hot melt adhesives,

especially for some low hardness and high viscosity materials

|

|

Strand

pelletizing system

|

Pelletizer for the processing of the melted polymer to cylindrical,

dry and easy to handle plastics pellets

|

|

Water ring

pelletizing system

|

Pelletizer for the production of various masterbatch,

filled and reinforced products etc.

|

|

Air cooling

pelletizing system

|

Pelletizer for the production of temperature and shear-sensitive plastics

|

Reference Values:

|

SHJ, series twin-screw extruder

|

|

Mixing nature-changing

|

PE,PP,PS+SBS,PA+EPDM,PP+NBR,NVA+silicon rubber,ect

|

|

PE,PA,PC,CPE+ABS(ALLOY),ABS+TPU,PBT+PET,PE+PP,ect

|

|

Filling nature-changing

|

PE,PP,EVA,ect+Calcium carbonate,talcum power,titanic powder,

ABS,PC,PS,ect+aluminum hydroxide,magnesium hydroxide,antimony

oxide.

|

|

PP,PA,ABS+ferrous powder,sulphuric powder,ceramic powder

|

|

Functional machine pellets

|

PP,PA,ABS,PBT,ect+burning agent and other auxiliary agents:combustion-

supporting machine pellets

|

|

PP,PE,PS ect +starch:de-composing machine pellets

|

|

PE+fog-preventing dipper,stabilizer:dual-prevention machine pellets

|

|

PE,EVA,ABS+carbon black:black machine pellets

|

|

Colored machine pellets

|

PE,PP,ABS,AS,PA,EVA,PET+pigment and auxiliary

|

|

Intensified glass fibres and carbon fibres

|

PP,PBT,ABS,AS,PA,PC,POM,PPS,PET,ect+long fibres,small fibres,c

arbon fibres,crystals and so on

|

|

Various cables

|

HDPE,LDPF,LLDPE,MDPE,EVA,PVCect+Insulating cables,coatings,

PE peroxide,silicon alkyl crossing cables

|

|

Special materials

|

EVA heat-melting glue,polyurethane,fluorin rubber,fluorin plastics,PPcigarette filtering material and TPR sole material

|

|

Reaction extruding

|

Polyamide condensate,polyamide melting polymerization,polyamide

polyethrne-adding,polycarbonate condensate,ect

|

|

Exhausting and Volatilization

|

Polystyrene oxide,high-absorbing resin,chlorine sulphur polyethylene

|

|

Powder paint

|

Polyester,ring oxide,lactide,polyurethane,acrylate

|

FAQ

Q1: Are you a factory or trading company ? How is you factory extrusion experience?

A: We are factory in Nanjing , 20 years experience on extrusion.Leading supplier in Nanjing city.

Q2:Where is your factory located? How can I visit there?

A : Our factory is based in 77 Tangtong Rd,Hushu,Jiangning District Nanjing , Jiangsu Province, China,

1) You can fly to Nanjing Lukou Airport or you can fly to Shanghai then take high-speed train to Nanjing South Railway Station.

2) We will arrange the pick up in Nanjing Lukou airport or South Railway Station

Q3:What can you provide for after sale service?

A:We can send engineers to your factory for installation and training if customers‘ required

Q4:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q5:Could you afford technician team to guide ours installation and commissioning?

A:Experience engineer oversea installation service provided.

Q6: Why choose you ?

A: 1) Quick response. Once we got the inquiries from you, we will reply you within 12hours.

2) Promising leading time. To guarantee the quality, the machine will be finished within max 20days.

3) Before leaving factory, all the machine will be fully tested.

4) Customized package(Wooden) will ensure a safety shipping.

.png) Contact Now

Contact Now