Product Description

With systems designed for producing hot melt glue pellets, we can efficiently and economically meet the needs of the masterbatch or pellets producer. We manufacture the EVA hot melt glue pellets extruder machine with the most advanced technology and best material, it can produce standard size of pellets, for better utilization by the end user. As the space requirement is not high, the energy cost is low, and the processing cost is low, so that our twin screw EVA hot melt adhesive pellets extruder machine more and more popular in many countries.

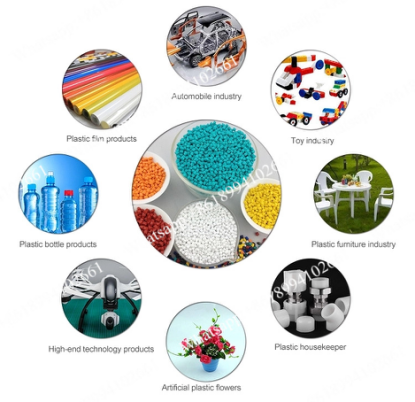

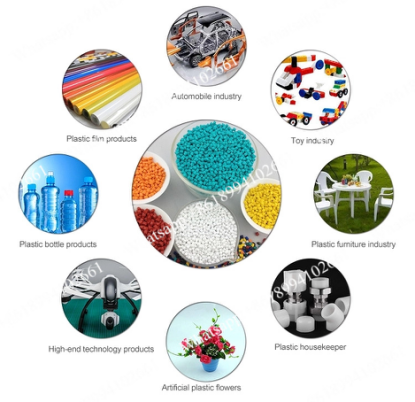

Applications of Twin Screw Extruder Machine:

· (1) Biodegradable material: PE/PLA/PBAT+starch/additives etc.;

· (2) Thick masterbatch:PE, ABS, PS, PP+ pigment, additives;

· (3) Flame retardant masterbatch: PP, PA, ABS+ flame retardant, additives, etc.;

· (4) Filling modification: PE/EVA+ calcium carbonate, talc powder,TiO2,carbon black, etc.;

· (5) Enhanced modification:PP,PA,PBT, ABS, AS, PC, POM, PPS, PET +glass fiber, carbon fiber;

· (6) Blending alloy: PC+ABS, PA+ABS, CPE+ABS, PP+EPDM, PA+EPDM, PP+SBS etc.;

· (7) Cable material: PVC、PE、low smoke and halogen free etc.;

· (8) Engineering plastics: ABS、PEEK、PC etc.;

· (9) Thermoplastic elastomer:TPU、TPE etc.;

· (10) Color masterbatch: PE, ABS, PS, EVA, PET, PP+pigment, auxiliaries;

· (11) Flame retardant color mother: PP, PA, ABS, EVA, PBT+flame retardant.

Co-rotating Parallel Twin Screw Extruder Features

1. Screw components designed by computer aids is kneading type, has excellent self-cleaning function, the new kneading block design effectively avoid the problems of overheating and energy consumption.

2. According to process system and formula requirements, the unit can optimize its L/D ratio, barrel structure, screw array, venting number and location, feeding method, electrical control methods etc. for rational allocation.

3. Granulation system: water-cooling strand pelletizing, air-cooling die face hot cutting, water ring die face hot cutting, Eccentric water mist hot cutting, water and underwater die face hot cutting and so on.

4. Application: Filling Modification, glass fiber (carbon fiber) enhance various kinds of master batch, rubber and plastics compounding, plastic alloys, functional master batch, Various kinds of electric cable material, reactive extrusion. Devolatilization process, powder coating and so on.

FAQ

Q1: Are you a factory or trading company ? How is you factory extrusion experience?

A: We are factory in Nanjing , 20 years experience on extrusion.Leading supplier in Nanjing city.

Q2:Where is your factory located? How can I visit there?

A : Our factory is based in 77 Tangtong Rd,Hushu,Jiangning District Nanjing , Jiangsu Province, China,

1) You can fly to Nanjing Lukou Airport or you can fly to Shanghai then take high-speed train to Nanjing South Railway Station.

2) We will arrange the pick up in Nanjing Lukou airport or South Railway Station

Q3:What can you provide for after sale service?

A:We can send engineers to your factory for installation and training if customers‘ required

Q4:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q5:Could you afford technician team to guide ours installation and commissioning?

A:Experience engineer oversea installation service provided.

Q6: Why choose you ?

A: 1) Quick response. Once we got the inquiries from you, we will reply you within 12hours.

2) Promising leading time. To guarantee the quality, the machine will be finished within max 20days.

3) Before leaving factory, all the machine will be fully tested.

4) Customized package(Wooden) will ensure a safety shipping.

.png) Contact Now

Contact Now