Product Description

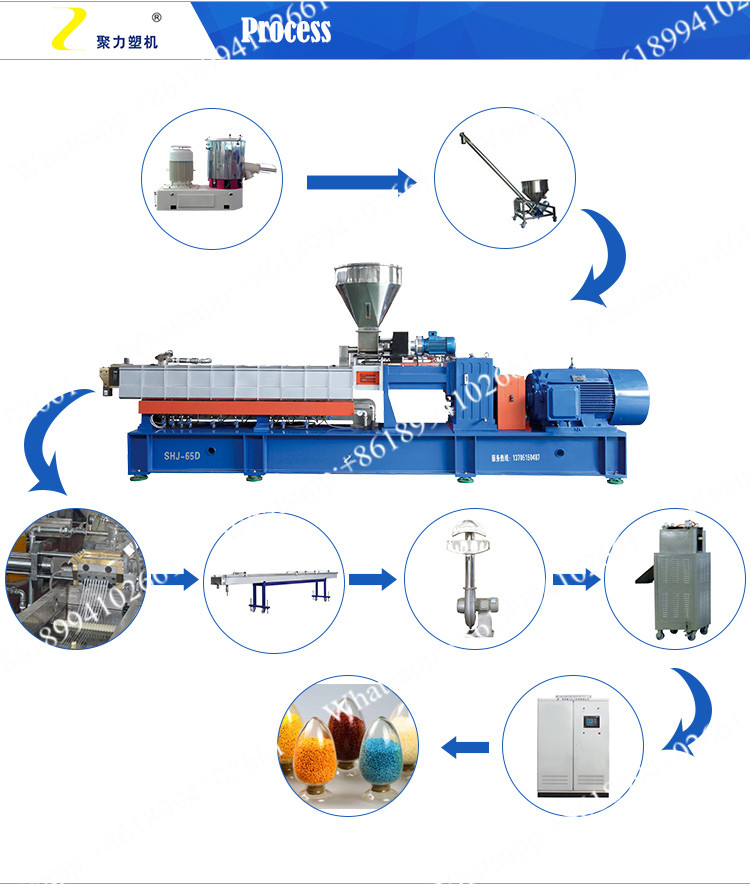

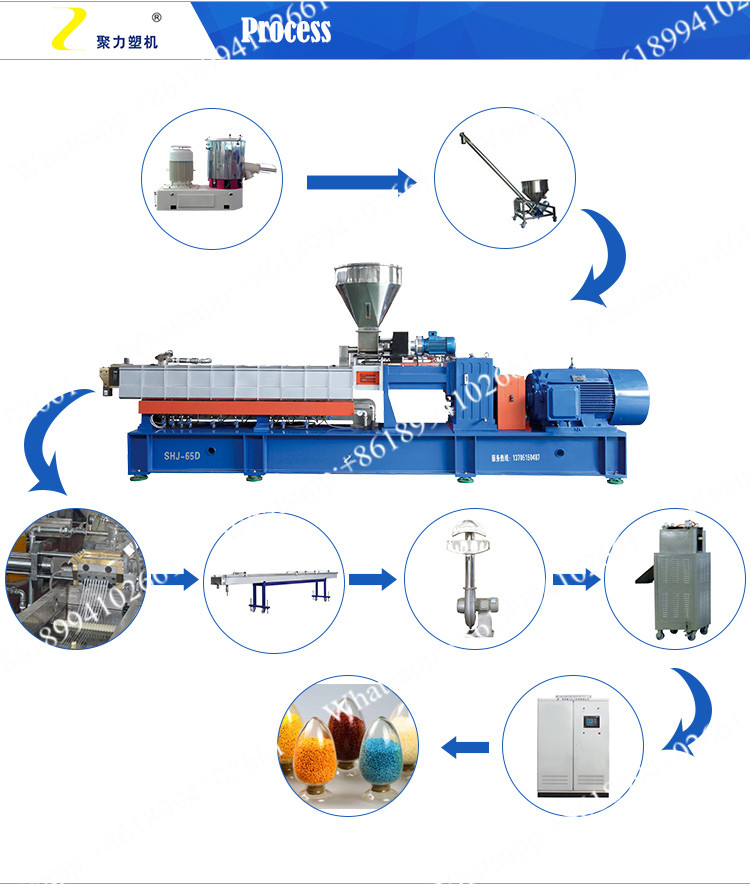

Plastic granulating line features :

1.twin screw extruder is parallel and co-rotation design, the screw is modular design and exchangeable. the barrel is segmented and exchangeable.

2.widely using for different process and material.

3.new designed gearbox and transmission system for high torque.

4.high precision gears, imported bearings and forced lubricating unit guaranteed high performance and reliable running.

5.more options for control system, i.e.PLCs, PECs,etc.

6.multiform pelletizing system for different solution, ie.stand pelletizing, die face pelletizing, water pelletizing, water-ring pelletizing, under water pelletizing.

7.easy arrangement and operation, no foundation required.

|

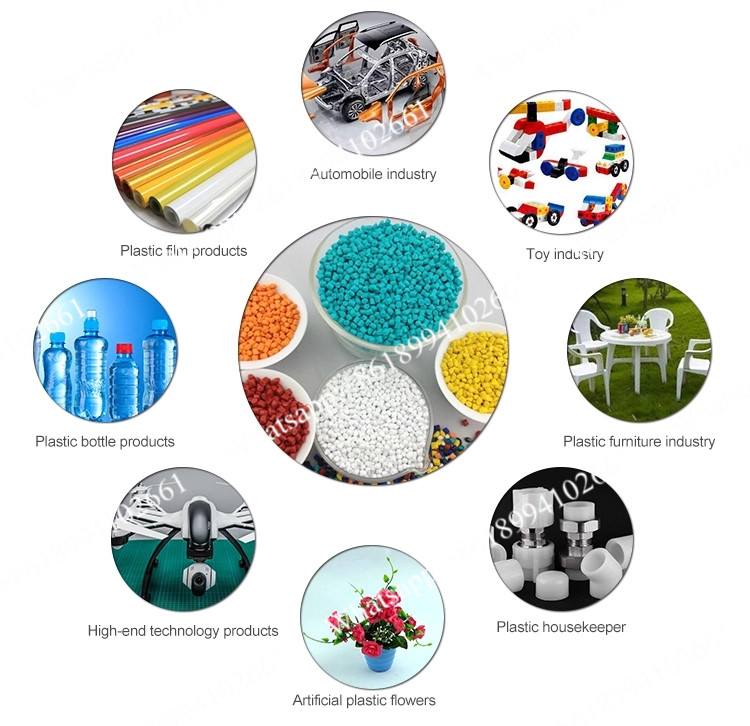

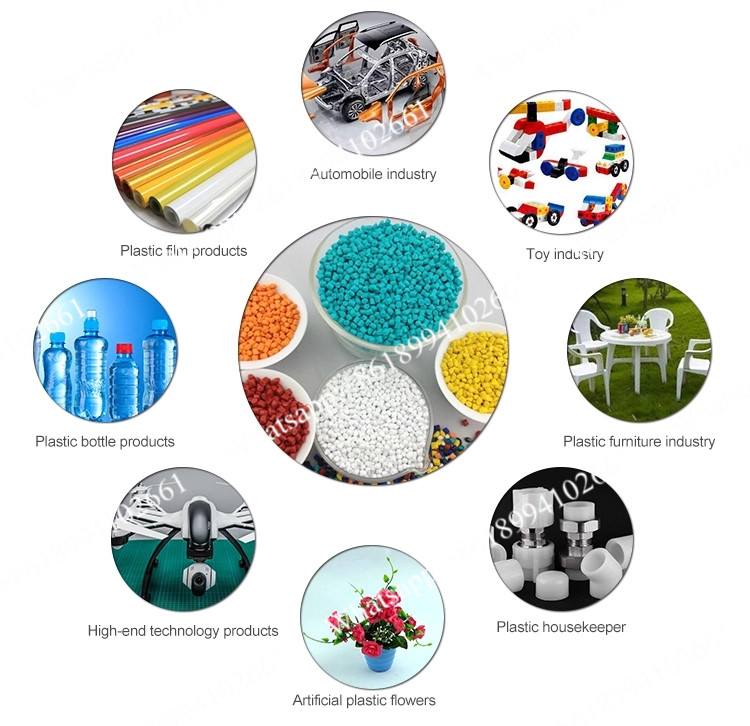

Fill modification:

CaCO3

Talc powder

Wood/Plat fiber

|

|

Masterbatch

Carbon black masterbatch

Color masterbatch

Flame retardant masterbatch

Degradable masterbatch

Other special-function masterbatch

|

|

Reinforced modification

Short glass fiber

Long glass fiber

Carbon fiber

Other whiskers

|

|

Compounding modification

Thermoplastics/Elastomer

Polymer alloy

|

>>Gearbox

Reduction transmission: High torque gearbox

Germany HENSCHEL / ZAMBELLO

Reduction ratio: I = 2.5:1.

Output power: P1 = 200 kW

Input speed N1 = 1500 rpm

>>Screw

Screw Kneading block built on modular principle allows various L/D

ratio of screw easily be changed to suit different material. Screw component

made of high speed & wear-resisting steel.

>>Barrel

By means of the replaceable screw barrel

sections, theprocessing sections is devided into individual zones. The barrels

are heated electrically. In addition, the barrels are provided with

longitudinal bores for cooling with water. Uniform temperature distribution,

namely on the circumference of the eightshaped barrel bore, is achieved by a

reverse forceflow temperature

control circuit. Connections of pipes for temperature control are

in groove-tongue design to balance alternating thermal stress and avoid

leakage.

FAQ

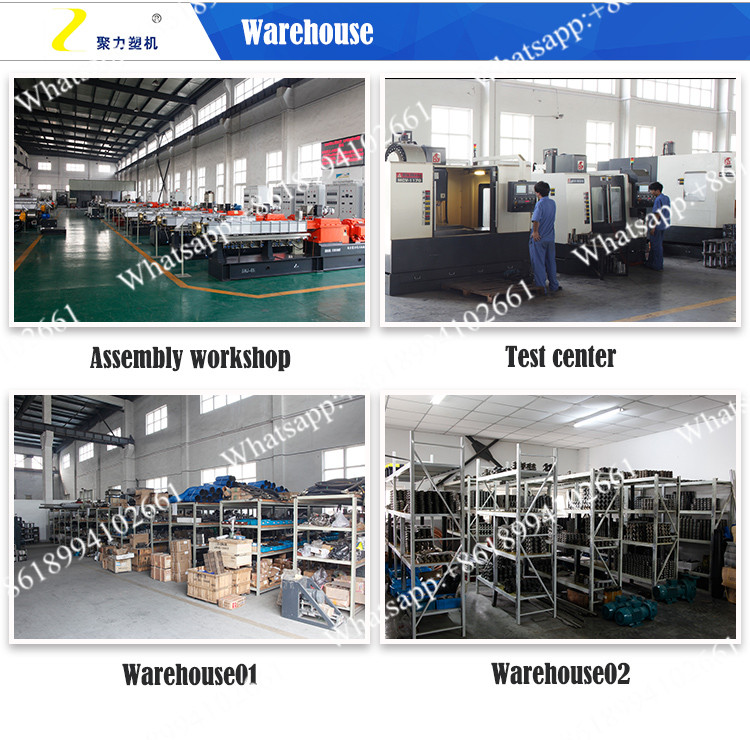

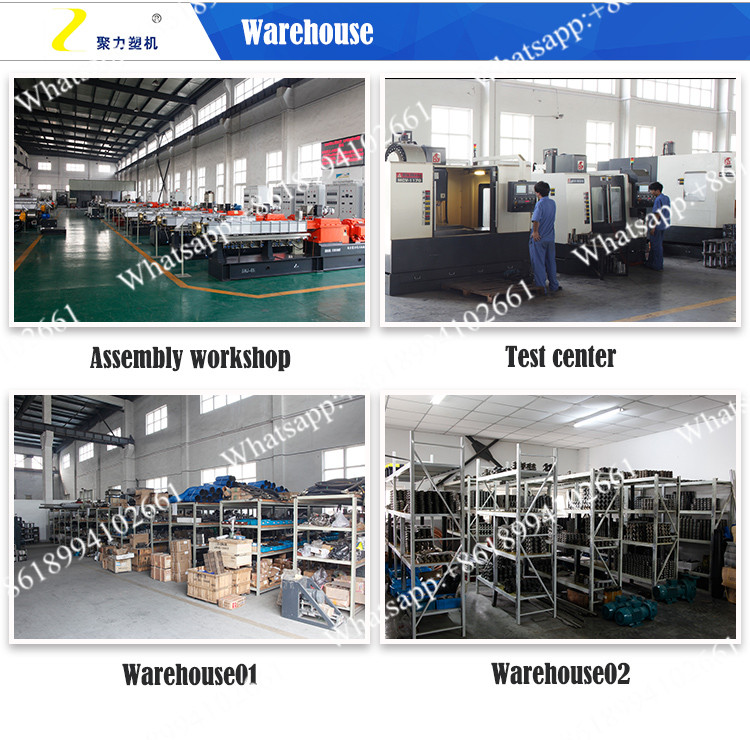

Q1: Are you a factory or trading company ? How is you factory

extrusion experience?

A: We are factory in Nanjing , 20 years experience on

extrusion.Leading supplier in Nanjing city.

Q2:Where is your factory located? How can I visit

there?

A : Our factory is based

in 77 Tangtong Rd,Hushu,Jiangning District Nanjing

, Jiangsu Province, China,

1) You can fly to Nanjing Lukou

Airport or you can fly to Shanghai then take high-speed train to Nanjing

South Railway Station.

2) We will arrange the pick up in

Nanjing Lukou airport or South Railway Station

Q3:What can

you provide for after sale service?

A:We can send engineers to your factory for

installation and training if customers‘ required

Q4:If we have very special request for the production

line,could you help me to do the design?

A:Experienced mechanical designer

customized-design provided.

Q5:Could you afford technician team to guide ours

installation and commissioning?

A:Experience engineer oversea installation

service provided.

Q6: Why choose you ?

A: 1)

Quick response. Once we got the inquiries from you, we will reply you

within 12hours.

2) Promising leading time. To guarantee the quality, the machine will be

finished within max 20days.

3) Before leaving factory, all the machine will be fully tested.

4) Customized package(Wooden) will ensure a safety shipping.

.png) Contact Now

Contact Now