Product Description

1. High-efficient force-feeder ensures high capacity feeding, low energy consumption.

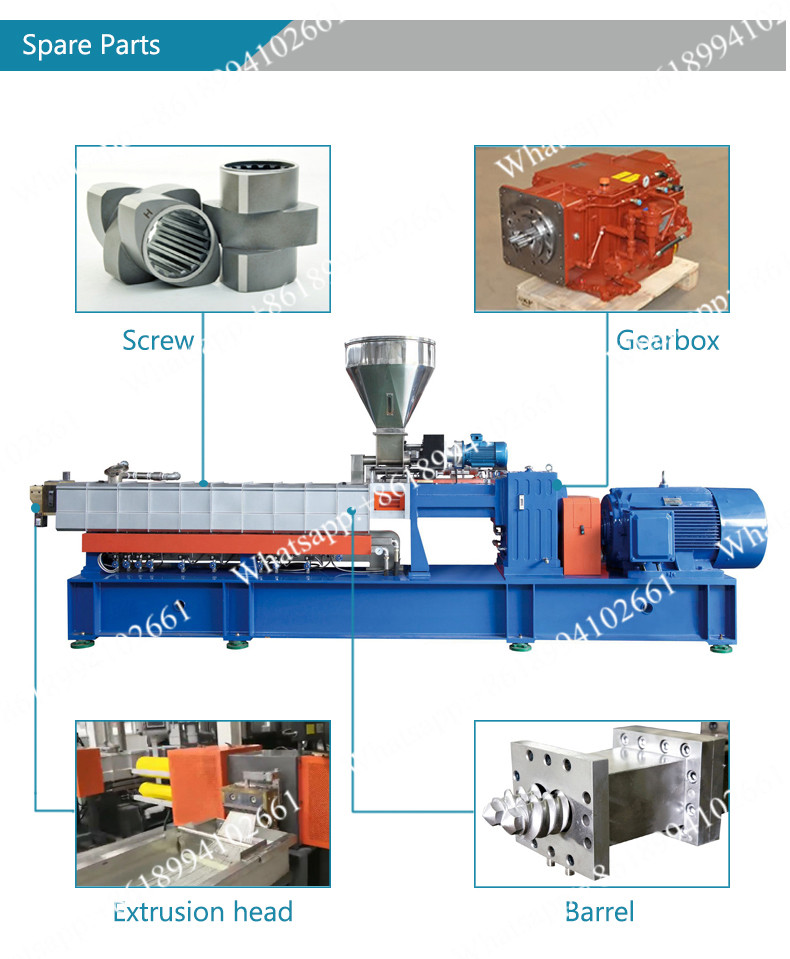

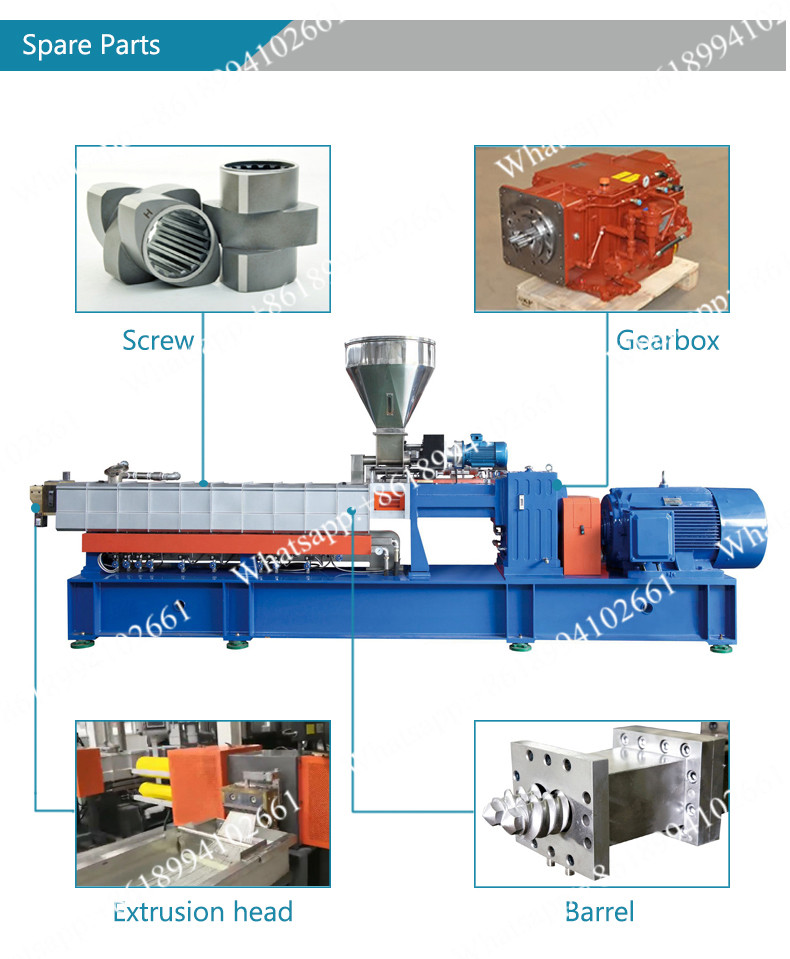

2. Twin screw extruder, equipped with specially designed screw & barrel, venting system, has a very good output capacity.

3.Pelletizing style: strand/water-ring/air cooling/under water pelletizing cutting with extrusion mould, even cutting ensures good shape.

Details:

1) Screw diameter : 22~133mm. L/D= 28~68

2)Main drive motor :AC 5.5~550kw,speed regulated by ABB transducer

3)Screw rotary speed:50~800rpm

4)Screw shaft is made of high-strength alloy 40CrNiMoA.

5) Barrel is totally 6~17 pieces of barrels

6)The 1st barrel is the main feeding vent, Generally speaking ,the 5th is for degassing,8th is vacuum section ,and the others are closed barrels.

7)Casting copper heaters for 2.3th barrels .The others are equipped with casting aluminum heaters.

8)Reducing and distributing gearbox:

The gearbox reduces the motor speed to the speed of the screw shafts and distributes it to the 2 output shafts,

this gearbox output torque can reach 7.5T/A3

The gearbox consists of:

l Involute gear teeth couplings between the output shaft and screw shafts

l Integrated thrust bearing assembly ,radial bearings of the output axis are NSK products

l Bottom part of casing designed as oil sump

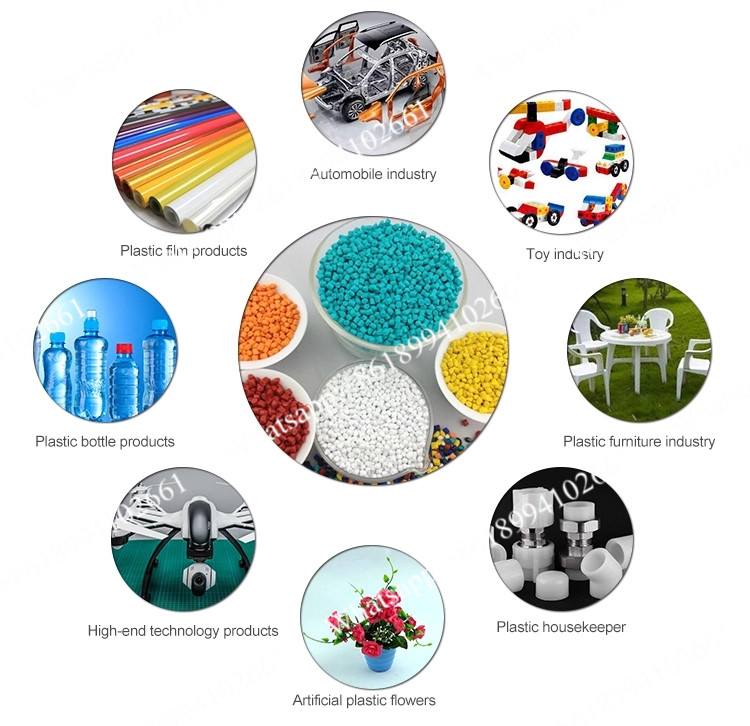

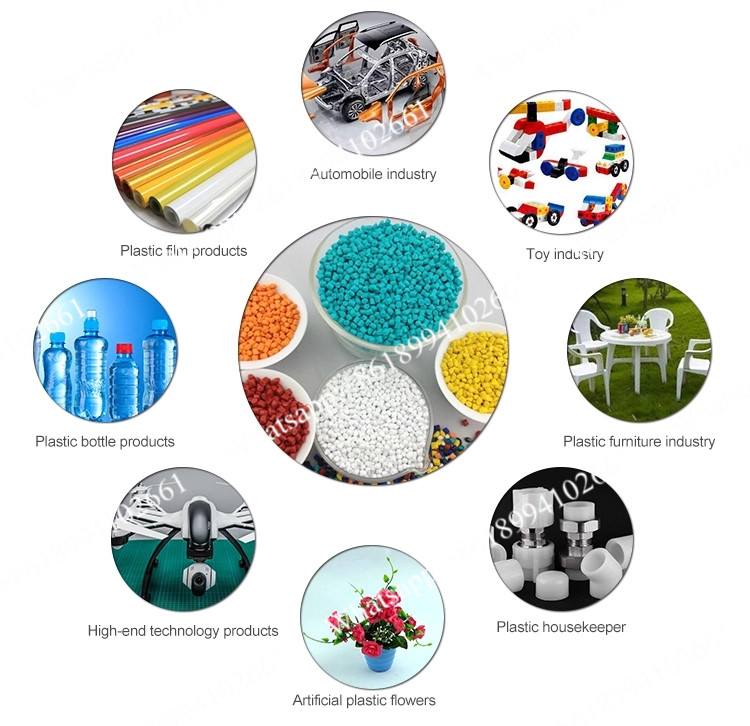

Applications of Twin Screw Extruder Machine:

· (1) Biodegradable material: PE/PLA/PBAT+starch/additives etc.;

· (2) Thick masterbatch:PE, ABS, PS, PP+ pigment, additives;

· (3) Flame retardant masterbatch: PP, PA, ABS+ flame retardant, additives, etc.;

· (4) Filling modification: PE/EVA+ calcium carbonate, talc powder,TiO2,carbon black, etc.;

· (5) Enhanced modification:PP,PA,PBT, ABS, AS, PC, POM, PPS, PET +glass fiber, carbon fiber;

· (6) Blending alloy: PC+ABS, PA+ABS, CPE+ABS, PP+EPDM, PA+EPDM, PP+SBS etc.;

· (7) Cable material: PVC、PE、low smoke and halogen free etc.;

· (8) Engineering plastics: ABS、PEEK、PC etc.;

· (9) Thermoplastic elastomer:TPU、TPE etc.;

· (10) Color masterbatch: PE, ABS, PS, EVA, PET, PP+pigment, auxiliaries;

(11) Flame retardant color mother: PP, PA, ABS, EVA, PBT+flame retardant.

FAQ

Q1: Are you a factory or trading company ? How is you factory extrusion experience?

A: We are factory in Nanjing , 20 years experience on extrusion.Leading supplier in Nanjing city.

Q2:Where is your factory located? How can I visit there?

A : Our factory is based in 77 Tangtong Rd,Hushu,Jiangning District Nanjing , Jiangsu Province, China,

1) You can fly to Nanjing Lukou Airport or you can fly to Shanghai then take high-speed train to Nanjing South Railway Station.

2) We will arrange the pick up in Nanjing Lukou airport or South Railway Station

Q3:What can you provide for after sale service?

A:We can send engineers to your factory for installation and training if customers‘ required

Q4:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q5:Could you afford technician team to guide ours installation and commissioning?

A:Experience engineer oversea installation service provided.

Q6: Why choose you ?

A: 1) Quick response. Once we got the inquiries from you, we will reply you within 12hours.

2) Promising leading time. To guarantee the quality, the machine will be finished within max 20days.

3) Before leaving factory, all the machine will be fully tested.

4) Customized package(Wooden) will ensure a safety shipping.

.png) Contact Now

Contact Now